Thanks John, I hope so.

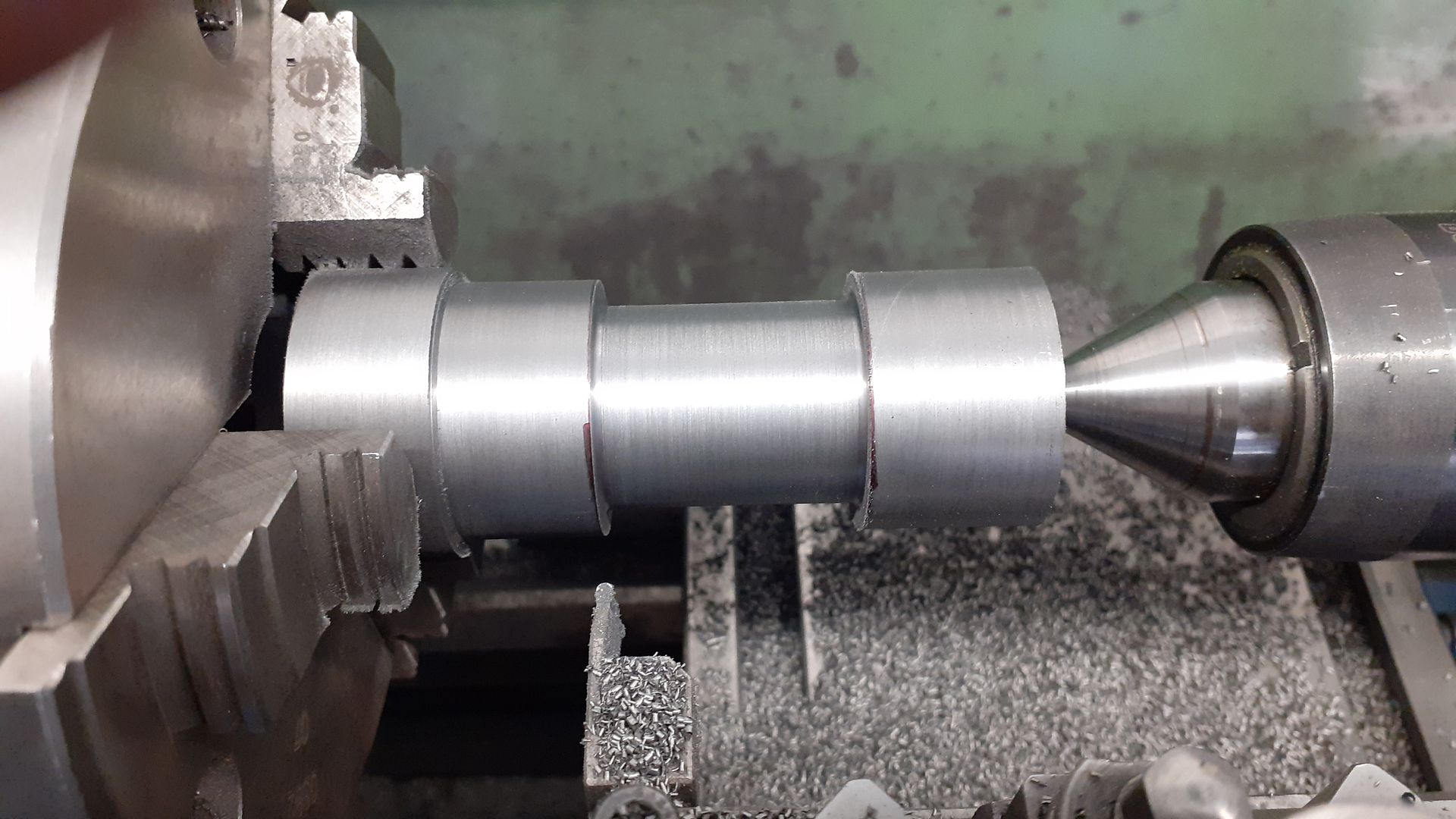

With the unwanted metal sawn off the cylinder jacket casting it was held in the 4-jaw to face the end flange, turn the flanges OD and finally bored to accept the liner. I spent some time getting the sides of the casting as square as possible to the chuck face as well as either end running as true as you can get with cast surfaces. I also took as much off the flange as was practical as the images of full size engines I was using for reference looked shorter than the casting.

The casting was then flipped around and the head end faced back, again getting as close to the boss as possible, in this shot 0.5mm has been left to be skimmed off after the liner has been fitted.

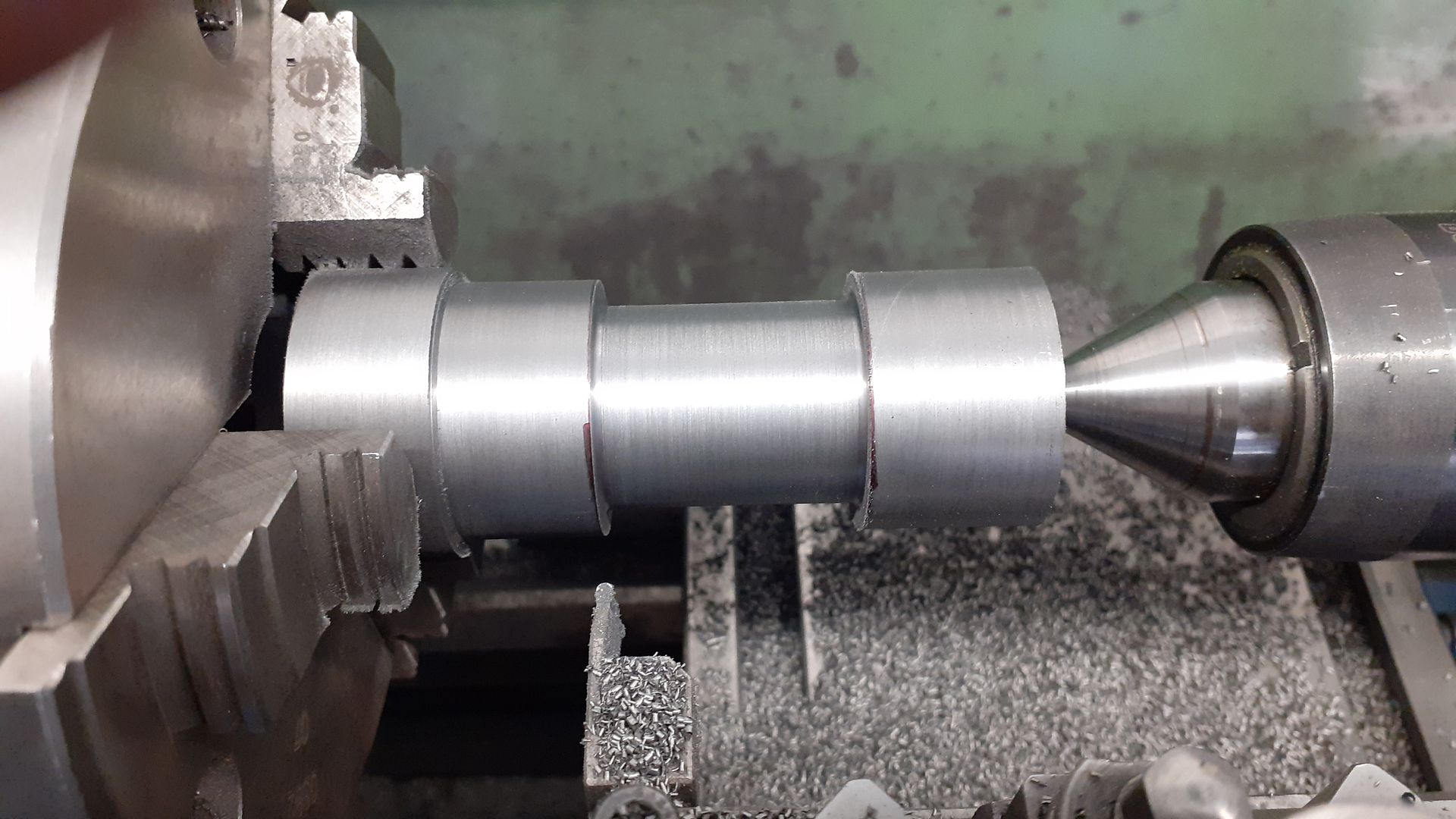

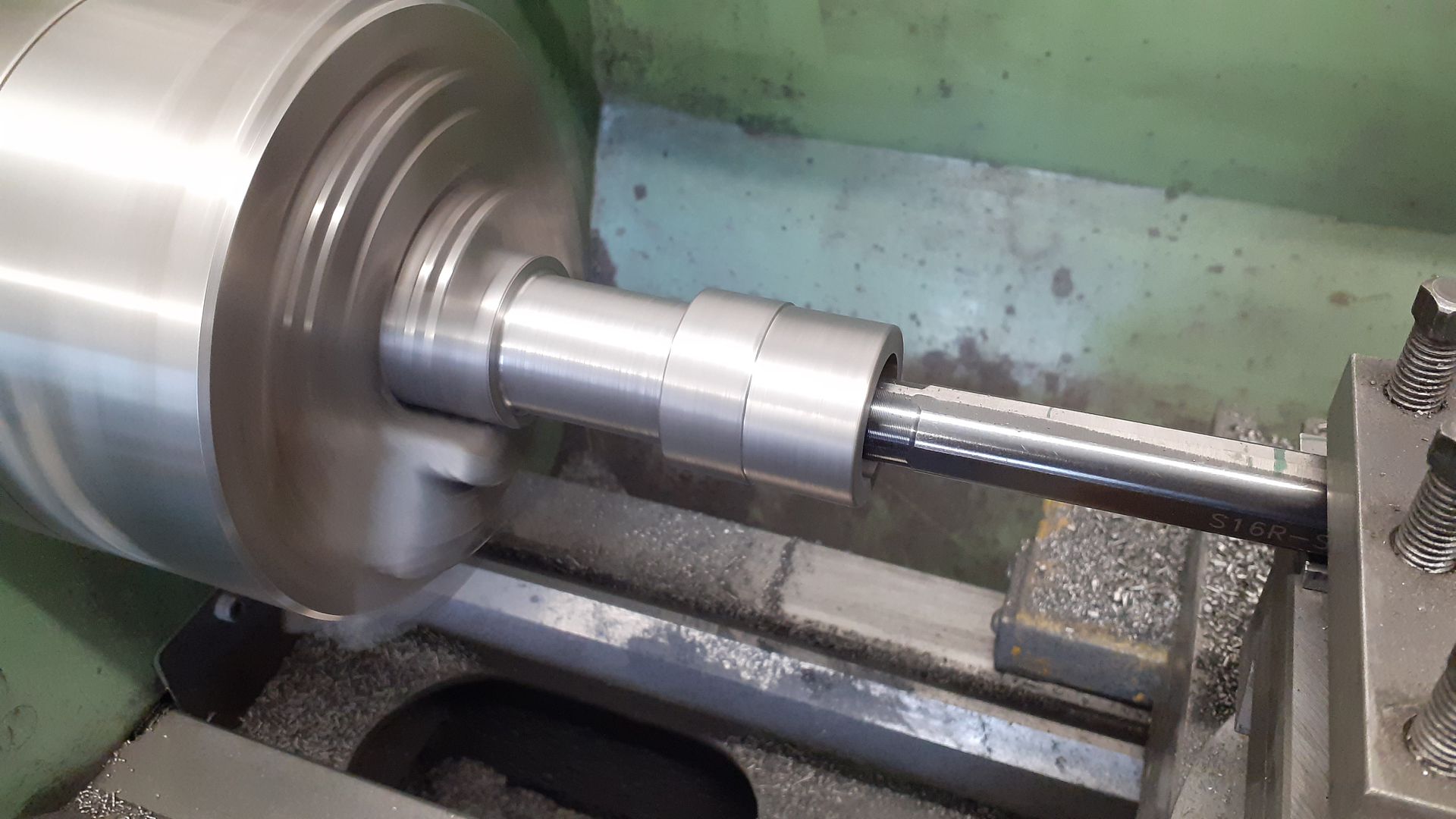

One end of some cast iron bar for the liner was cleaned up and then held by that section to turn the OD and cut a waist that will become the water space. I used tailstock support while doing this.

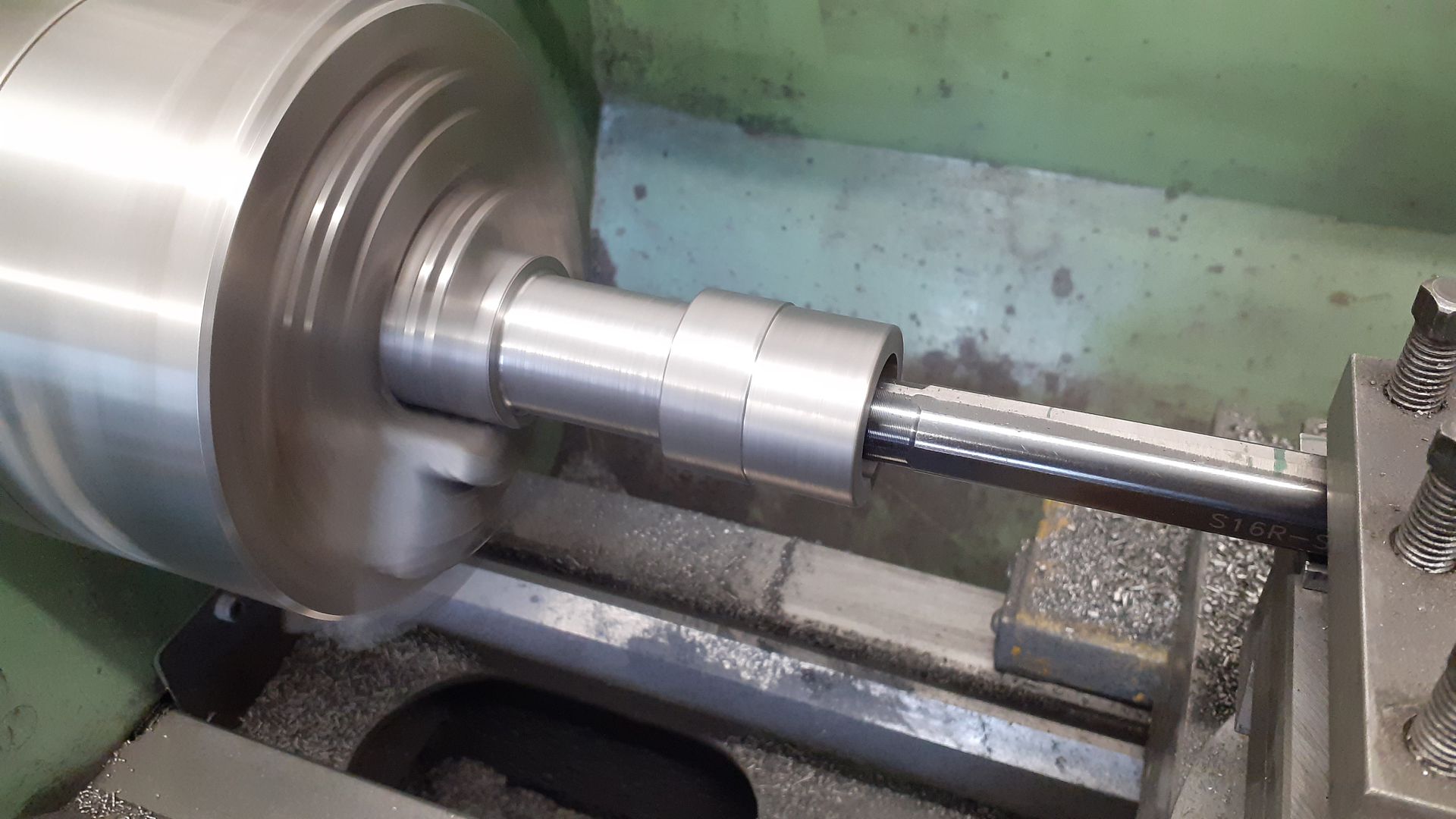

Gripping by the other end the chucking diameter was taken to it's final size and the cylinder drilled to 22mm and then bored to the final 24mm finished size after which it was loctited into the jacket with #648

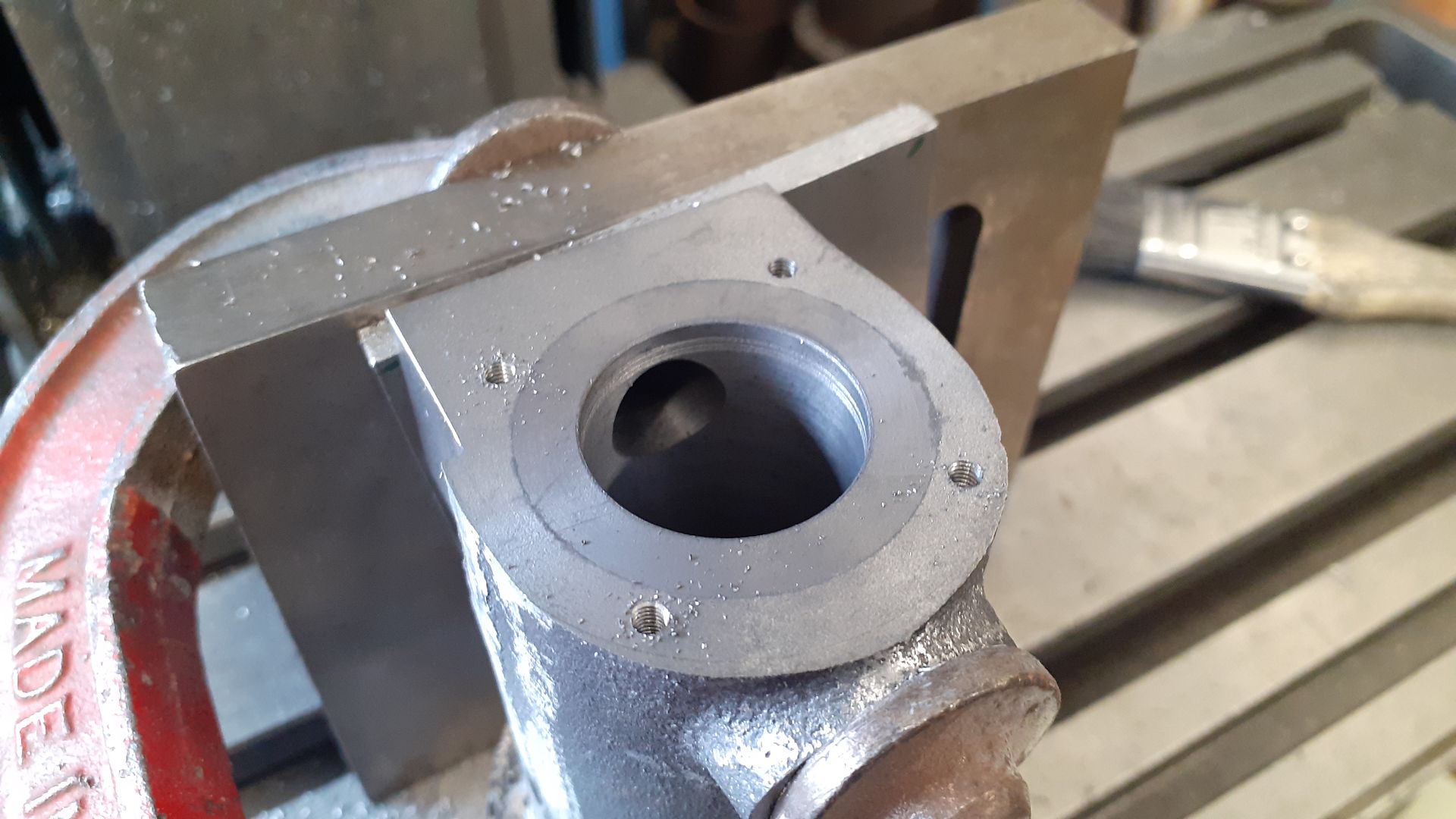

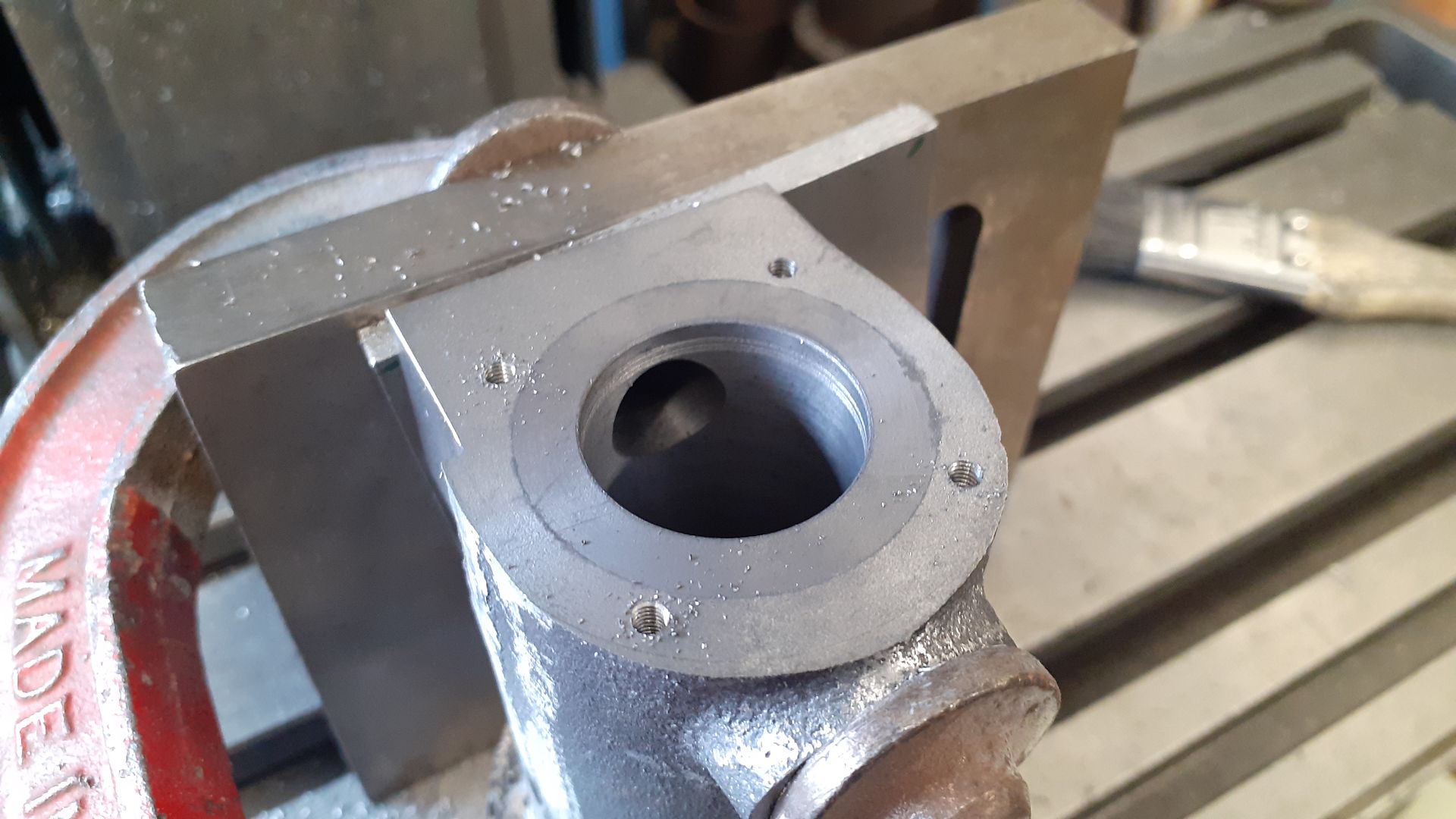

After a couple of days to make sure the loctite had set the 0.5mm was faced off the end of jacket and liner to give a true flat surface for the cylinder head to seal against. Then the 100mm vice was mounted lengthways on the mill table so that the assembly could be further machined. Firstly the exhaust block was milled to height and reamed to take the valve cage and it's two retaining stud holes drilled and tapped. A water inlet hole was also drilled and tapped and lastly at that setting one side of the exhaust block was milled flat to later receive the side shaft bracket.

Turning the cylinder the other way up the tops of the various bosses were milled to their required heights, the central one tapped for the water connection and the one at the head end tapped and counterbored for a 1/4" x 32 Rimfire plug. The smaller one will get drilled to suit what oiling method I decide to eventually go for.

Lastly the two stud hole patterns were done on the flange and head ends

Recent Posts

Recent Posts

Its a lot of the reason I like the larger scale models, more room for little working details.

Its a lot of the reason I like the larger scale models, more room for little working details.