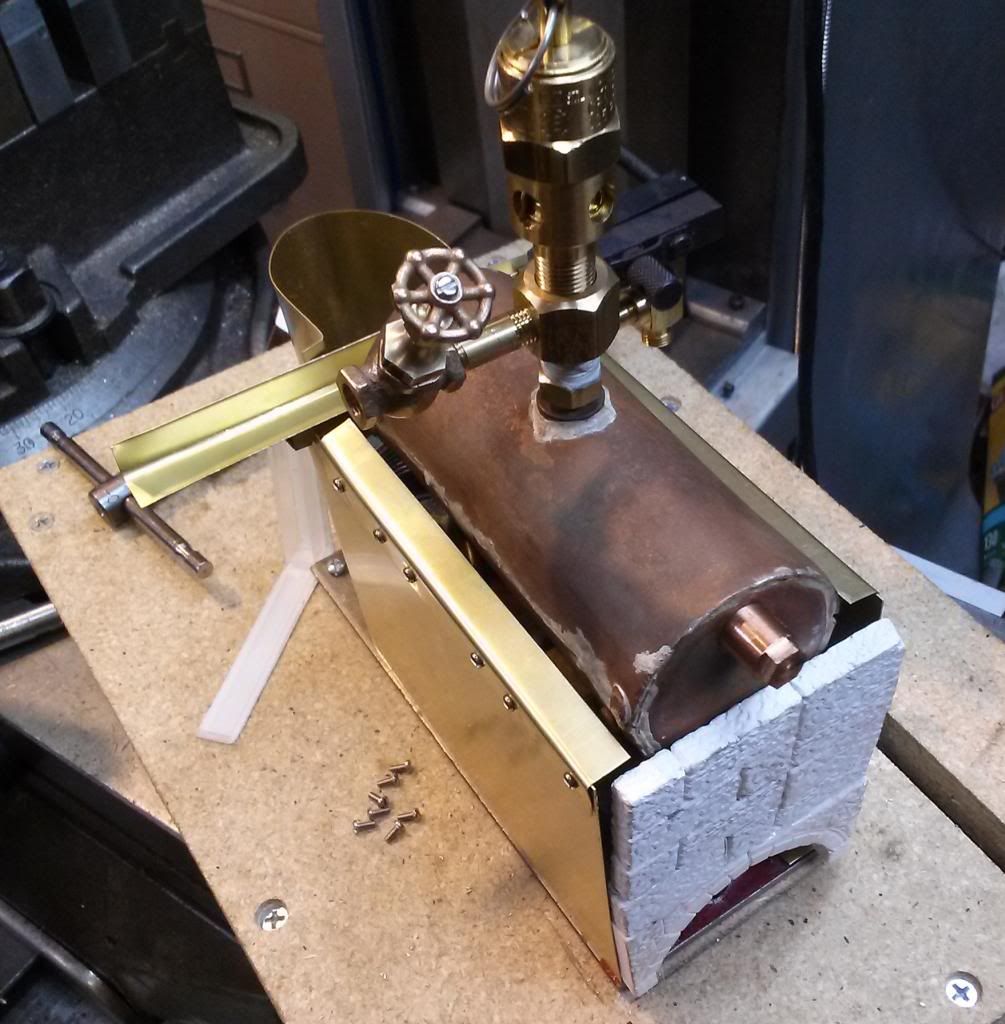

Well, moving on, every boiler needs at least one valve, enter another of PMR's high quality casting kits.

I didnt document the valve build very well. From the first moment I read the prints I feared the long turning job on the valve stem. Lacking a steady rest or any follower setup for my lathe, I attempted the "full cut at one time towards the headstock" method with something I hesitate to call success, although it was servicable, barely. The stem did turn out quite triangular. I will have to remember that stuffup when it comes time to make a wankel.

At this point, it was time to light a fire and see what happens.