Hi Guys,

Wow where does the time go? It has been a month already since my last update.

Starting work on the main stop valve spindle; first it is faced and turned to the major diameter of the part.

Next the smallest diameter is turned.

And before the part gets too flimsy the point is added.

Then the rest of the valve is turned.

The decorative radius is added using a form tool.

The 3-48 threads are added using a tailstock die holder.

Then it is parted off leaving enough material to finish the other end.

The valve is finished the same as the fill plug; a 1-72 drilled and tapped hole and two 1/16” posts that will fit into holes in the wood knob.

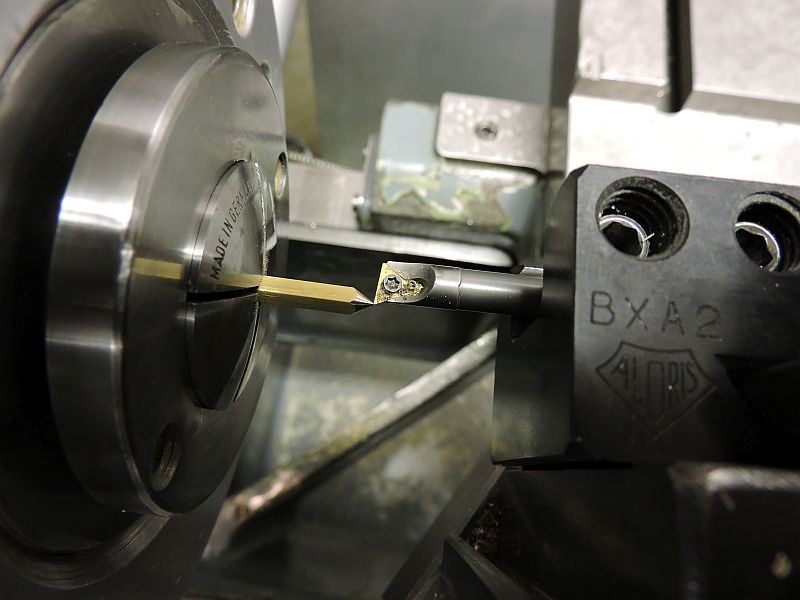

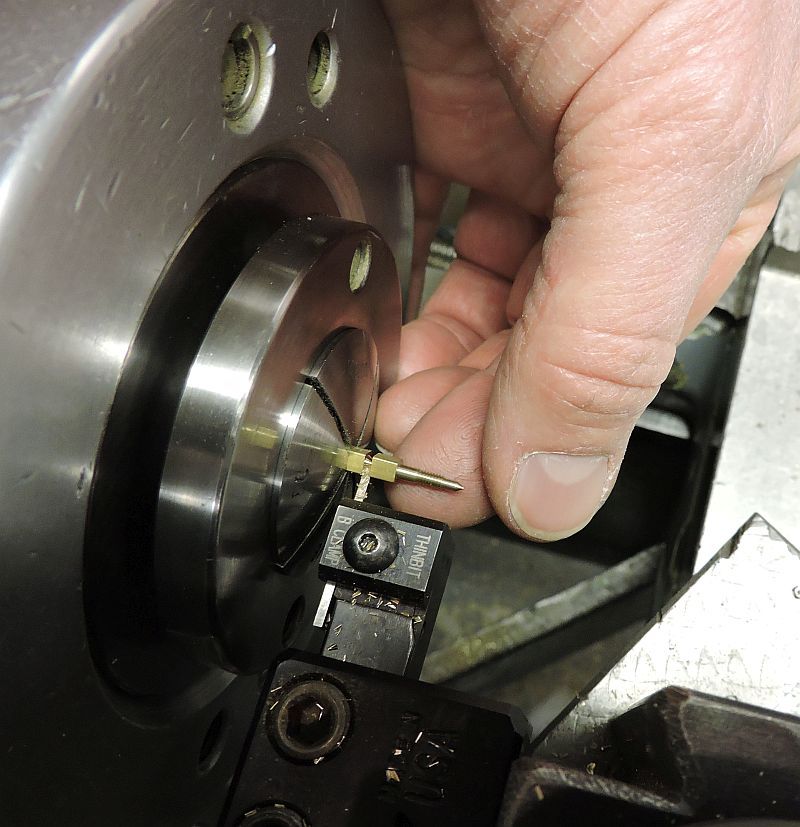

The smaller metering valve is made much the same way as the stop valve. I started out by turning the point first using a boring bar on the back side running the lathe in reverse.

Using the same tool the rest of the turning operations are completed.

The 2-56 thread is also added using the tail stock die holder.

And then parted off.

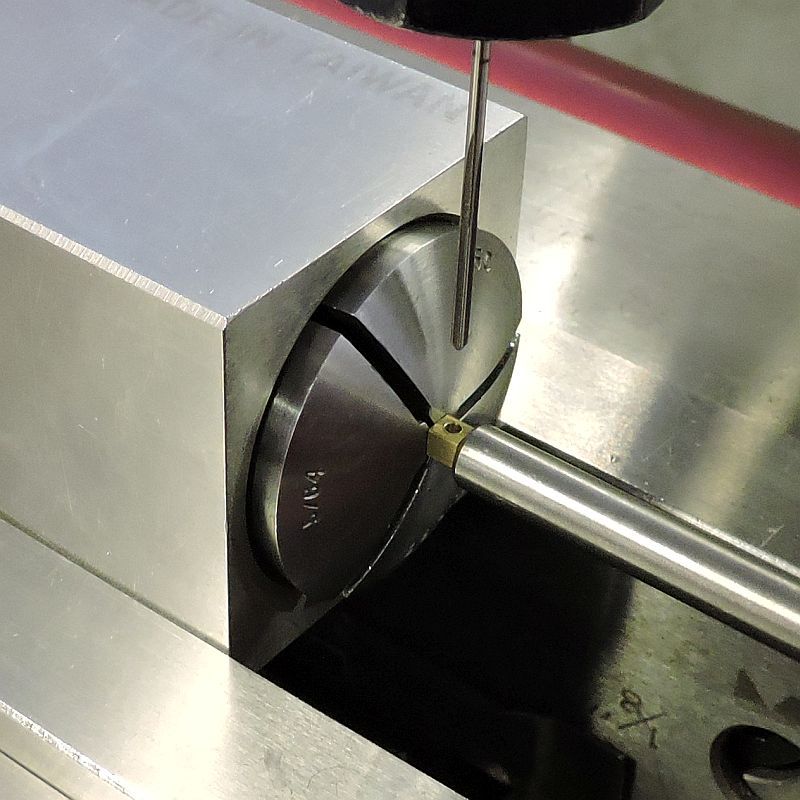

After the valve was flipped around and faced to length is was set up and squared in a collet block to drill and ream the cross hole.

A vise stop was used to reference the end of the valve.

And the hole was drilled and reamed for a press fit of the 1/16” cross pin.

The cross pins were turned with a dome on each end (like the original) and pressed in place.

Next up I will continue with the machining of the two wood knobs and hardware.

Thanks for checking in,

Dave