Hey all,

I'm going through some adjustments on my mini-lathe and am (finally!) turning on centers. I had already lined things up with a 1" rod extended from my 4-jaw chuck and all is well, so I figured turning between centers and adjusting the tailstock was the next step.

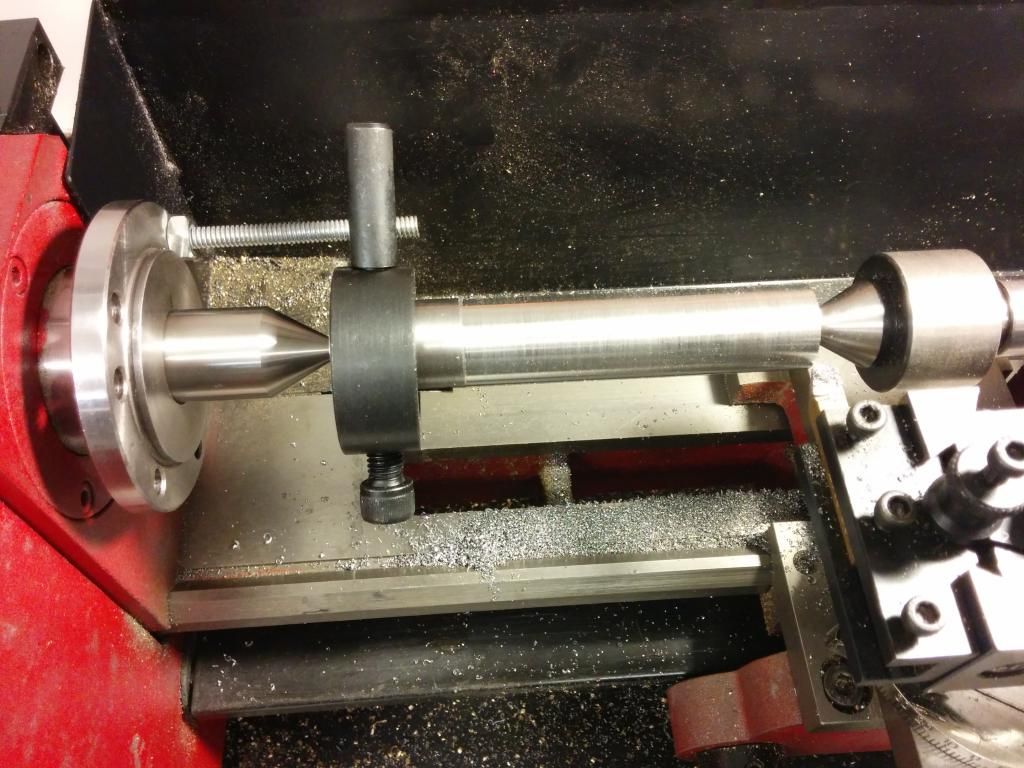

First, a photo of the ugly setup. I am unhappy that my MT3 dead center is HUGE for this lathe. Are shorter ones available? I'm under the assumption it's hardened and not realistic to machine it down. Driving the dog seems a bit precarious to me, not to mention the wasted space on a lathe that has little to spare.

After turning this rod, I found the tailstock end was 0.012 inch larger in diameter. I found I had to loosen a little slotted screw on the end, but there was also a socket cap head screw underneath the tailstock. Has anyone found a way to get under there without removing the tailstock?

I found I had to loosen the screw underneath while the slotted screw remained tight, reinstall the tailstock, loosen the slotted screw, tap very carefully with a DI measuring my progress, tighten the slotted screw, *CAREFULLY* pull off the tailstock, flip over, and tighten the socket cap screw. Geez...can they make it any easier? On my first attempt I tapped away 0.006 inch, but managed to go over a bit. It's now 0.003 under.

I'm sure I can get it on the next couple attempts, but I'm posting on the off chance there is a better way. I'd like to be able to turn tapers and don't want to fear messing with the tailstock.

Todd