Thanks for the interest guys.

The displacer cylinder is provided as a length of pipe with the correct internal and external diameters. A flange, to allow it to bolt on to the bottom of the base needs silver soldering on and the end needs closing, again by silver soldering on a thin piece of steel.

I tuned up the flange from an off cut.

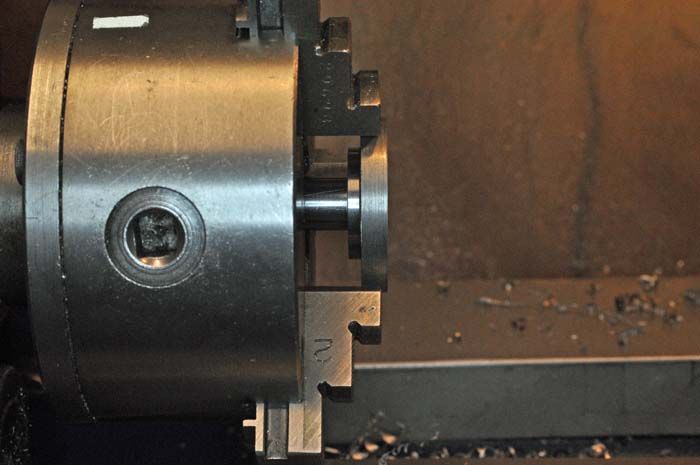

Here I'm using back stop to hold the flange blank so that I can cut it to the correct thickness.

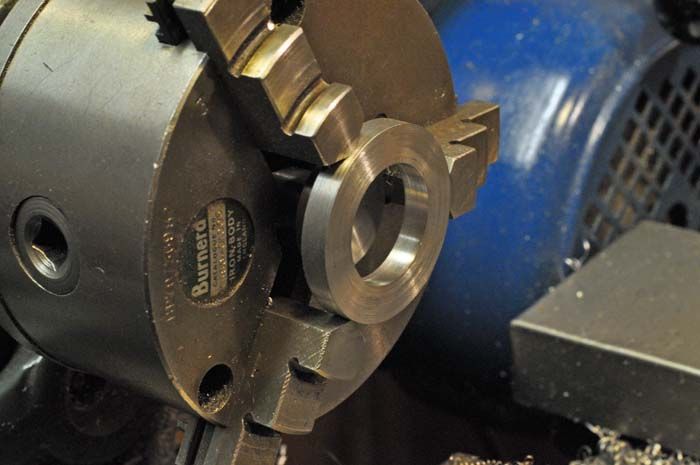

And then bored through so that it is an easy sliding fit on the pipe

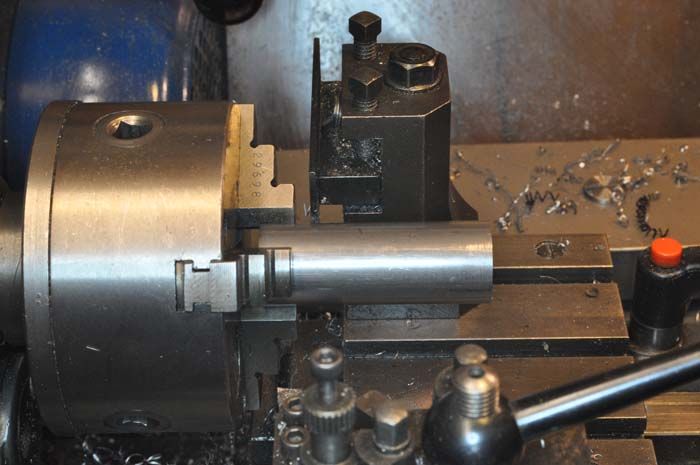

The pipe was parted off to length

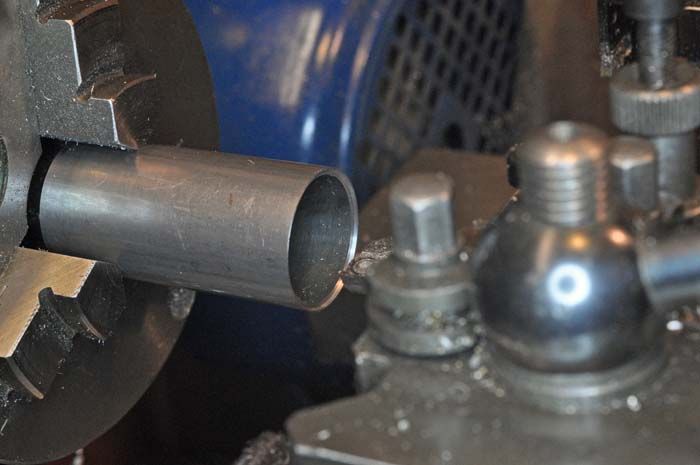

and then recessed to take the end piece

I trimmed a piece of sheet steel with some snips -

- before sizing between 2 pressure pads, sourced again from the oddments draw. I had to take very gentle cuts to avoid slippage. Until I'd made the blank round , it was actually more successful to feed the side of the tool against the blank than to turn in the conventional manner. The blank was an easy fit onto the recess in the pipe

These are the three bits that need soldering together

I made rings of silver solder to fit - the solder is 1/16" wire, almost certainly Easyflo 2 since I've had it for a long time. I cleaned everything with coarse new Scotchbrite. The Easyflo flux was mixed with water and applied to all the joint areas before assembly and then liberally plastered over everything

Heated with a Mapp type gas torch, I aimed at the base first to get that warmed up and then concentrated on the middle of the pipe. It flowed very nicely.

And I was very happy with the penetration

Cleaned up with more Scotchbrite, the flange was trimmed so that the pipe can locate in the baseplate and then I drilled the holes by spotting through from the base

I thought that went rather well