1

From Plans / Re: Upshur's twin opposed cyl. engine

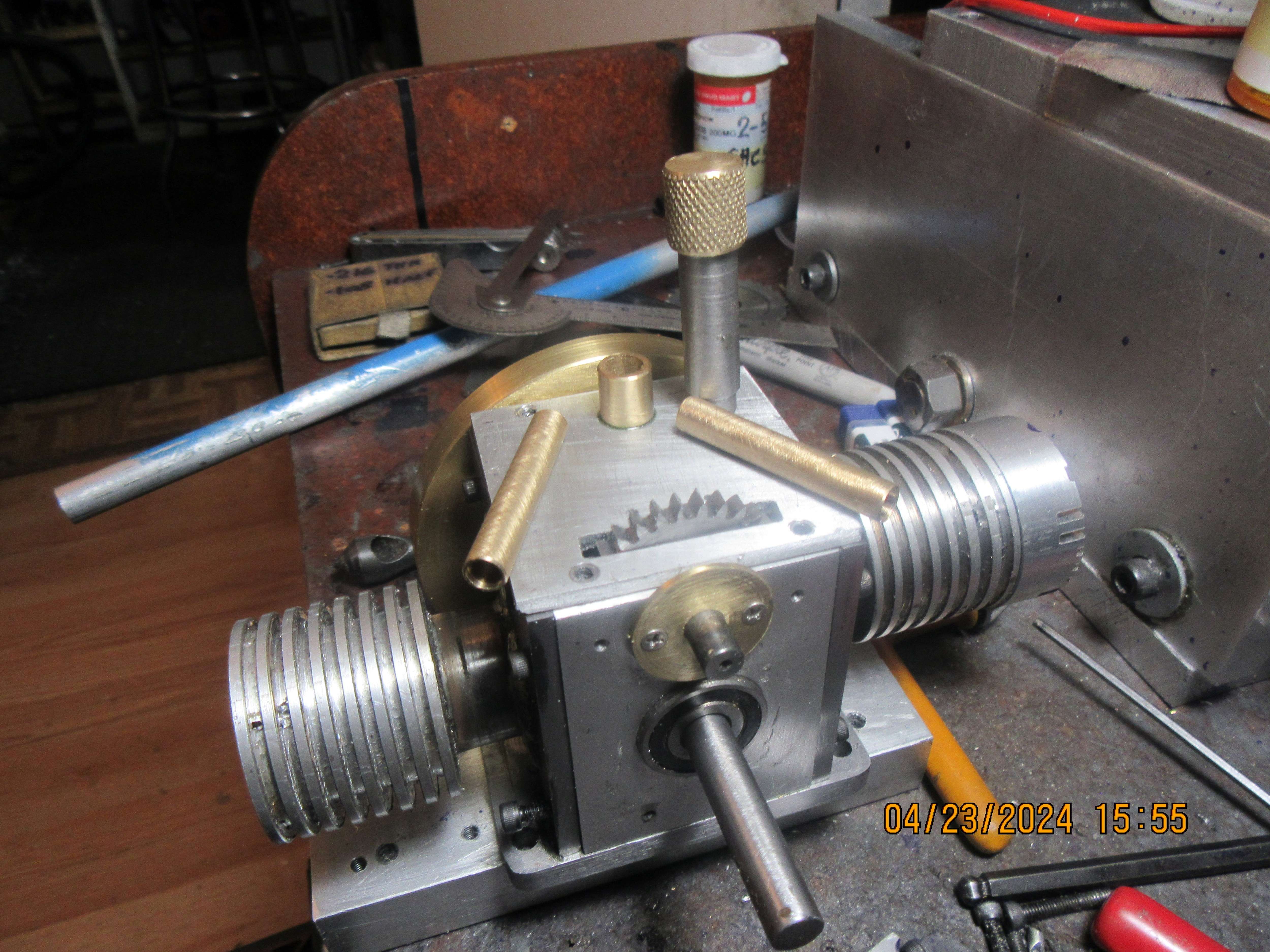

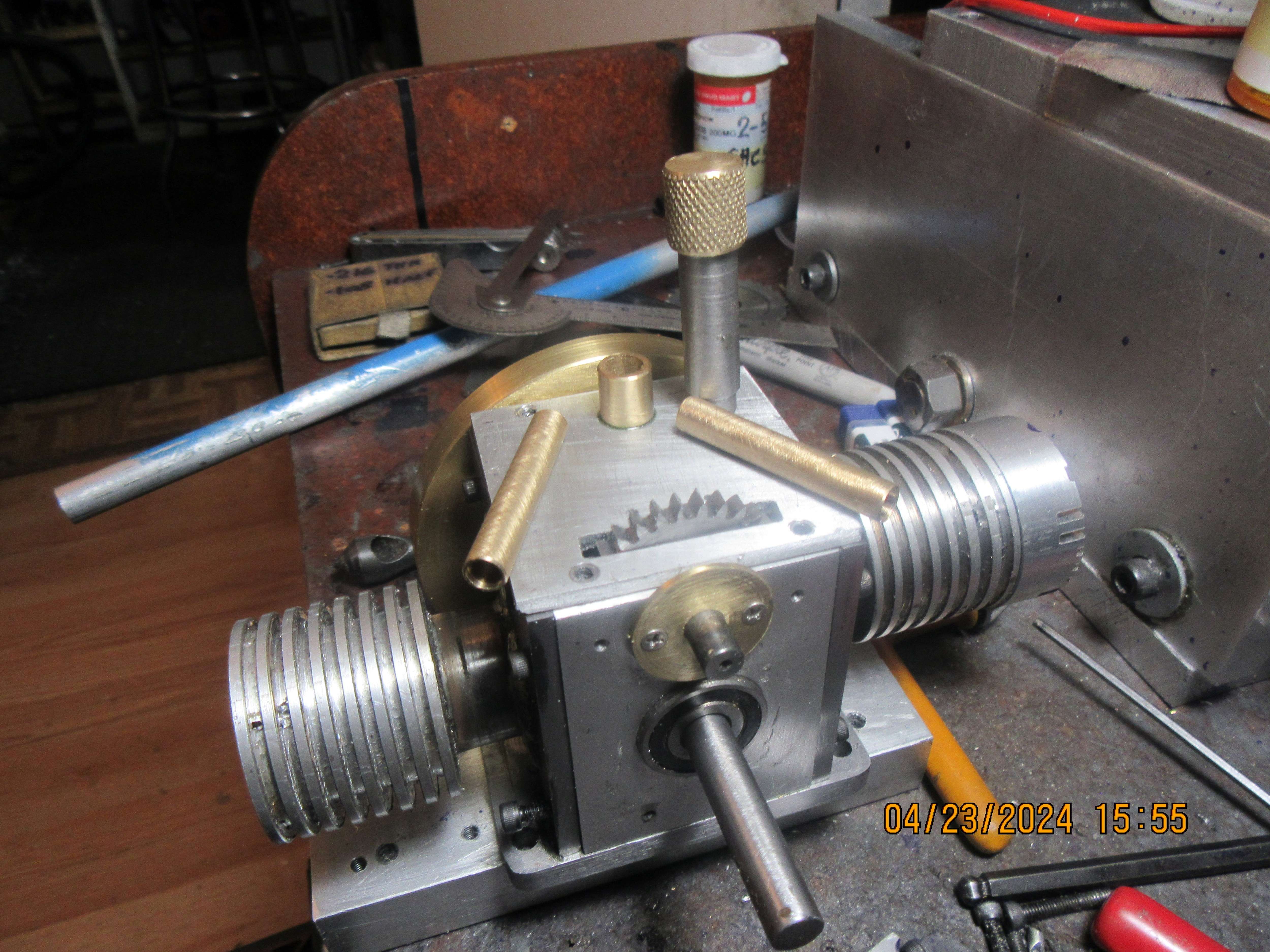

« Last post by Brian Rupnow on Today at 09:17:33 PM »Today has been a laid back kind of day. I made the oil filler tube and Loctited it into place, made the oil filler cap and right now it is mounted on a short piece of 3/8" shaft so I can cross drill it. I also made up the distributor ignition adapter plate and made up both exhaust pipes. That's not a lot, but somehow it has filled up most of my day.

Recent Posts

Recent Posts