Someone who I communicate with over on the Model Engineer forum asked me if I would review my experience of the Wabeco CC-F1210 milling machine and put it up on that forum.

Due to differences of opinion with the moderators on the ME forum I will not post content there any more, so I said I would write the review on another forum.

So Dave (Silly Old Duffer) here is what you asked for.

A little over two years ago, I had a work contract that would require me to machine batches of stainless steel components with 3D toolpath’s, I looked at two machines seriously and many others but did not get to the quotation stages on the latter.

I also wanted to use the machine for hobby related projects for my competition model aircraft.

F3D radio control pylon racing models.

F3D radio control pylon racing models.I narrowed my selection down to the Tormach 1100 and the Wabeco CC-1410, I received quotes from Tormach directly and from Pro Machine Tools who represent Wabeco in the UK. There was not much cost difference in the machines when push came to shove. Tormach had brand ambassadors in the UK who prospective customers can speak to for a personal experience of the machines, one of these ambassadors did not speak that well of Tormach which I found a bit strange.

Any how with the prospect of importing the machine from the USA and a some what distant support setup, I decided to go with the Wabeco machine. I had visited Pro Machine tools and seen the milling machine working and I already had a little experience dealing with Pro Machine tools as I had bought EMCO spares from them over a few years.

About 10 days before placing the order for the Wabeco mill a slightly different specification Wabeco mill came up for sale on Ebay, the machine was the dovetail slide rather than linear bearing version and only had 150mm Y axis travel rather than 180 on the 1410 version. The seller said the machine had only been used for about 60 minutes and was essentially brand new although actually 6 years old. I decided to go with this new/second hand machine as it was a little less than 60% of the new machine price.

The machine had been well specified, it came with an enclosure meeting CE requirements which includes a 10 gallon coolant sump and pump system, the machine and enclosure was fitted to the factory supplied cabinet stand. The 1210 mills from Wabeco have a 500x150x280 mm working envelope and a 2 HP motor driving the spindle at speeds from 140 rpm to 3000 rpm with speed being monitored and compensated for according to load.

The machine comes ready to use apart from getting the mill up onto the stands, everything is wired up at the factory and all motors and limit switches are mounted. The machine looks pretty good in this state and is well finished, I would say pretty comparable with EMCO or similar machines on presentation and finish. The machine is supplied with a factory test and measurement report with all of the standard measurements that you would expect and is checked to DIN standards 874, 875 and 879.

Wabeco make the machine tools in Germany and I have seen factory photo’s that confirm this, most of their accessory parts are sourced in the far east with Vertex being a main supplier, in fact my machine had been supplied new with a Vertex vice and ER25 collet holder, although Pro Machine tools had supplied EMCO collets which are in fact made in Germany by Fahrion.

Wabeco buy the control system and software from another German company called Max Computer who also supply Proxxon with the control system and software for their range of CNC machines.

The Max Computer software is called NCCAD and this aims to be a complete CAD/CAM and machine control software all built into one programme, I do my CAD in a number of different programmes according to the task, Bricscad and BobCad for 2D and Alibre Design Expert, MOI and BobCad for 3D, I do all my G-Code generation in BobCam, I produce code for 8 different machines with BobCam, one of the machines is a £120,000 machining centre that I have never even seen but the 3D results are stunning, I digress. The long and short is that I have not really used the NCCAD for 2D or 3D model creation, rather I have thrown G-Code at it which has been produced in BobCam.

There are some engraving routines in the NCCAD that can be called up by G-code and these give good results.

There are some engraving routines in the NCCAD that can be called up by G-code and these give good results.The machine control is fairly basic in comparison with newer PC based controls such as Eding NC or Kinetic NC but it works reliably. I would say that the stepper motors are not being driven hard by the control system as the axis accelerate and de accelerate quite slowly. If a jam occurs against any axis, you don’t get a feeling that the machine is going to do itself any harm as the steppers just stall out. The control has 20 different zero points that can be saved and stored (like G54-59), this is useful if you leave a vise or fixture semi permanently bolted to the mill table.

The machine is very accurate in positioning via it’s ball leadscrews, I have some video’s of positioning tests on You Tube if people are interested.

A big difference between the Tormach and the Wabeco, is that the Tormach is a ground up designed CNC machine, so it does not have a moveable quill in a drilling machine style and it has no hand wheels. The Wabeco is a converted manual machine that still retains hand wheels on all three axis and has a drilling machine style quill, there is a key switch on the control panel for switching between manual and CNC operation, the spindle is software controlled only for on and off, the speed is set manually on the control panel, the hand pendant has a feed over ride but the range is a bit limited. Wabeco CNC mills and lathes with their high speed spindle, have spindle speed controlled by G codes, my machine has the low speed spindle. There is an expansion port on the rear of the control panel which can control external devices such as HF spindles, I have had my 50,000 rpm Jager spindle running from this port and then speed is software controlled as well.

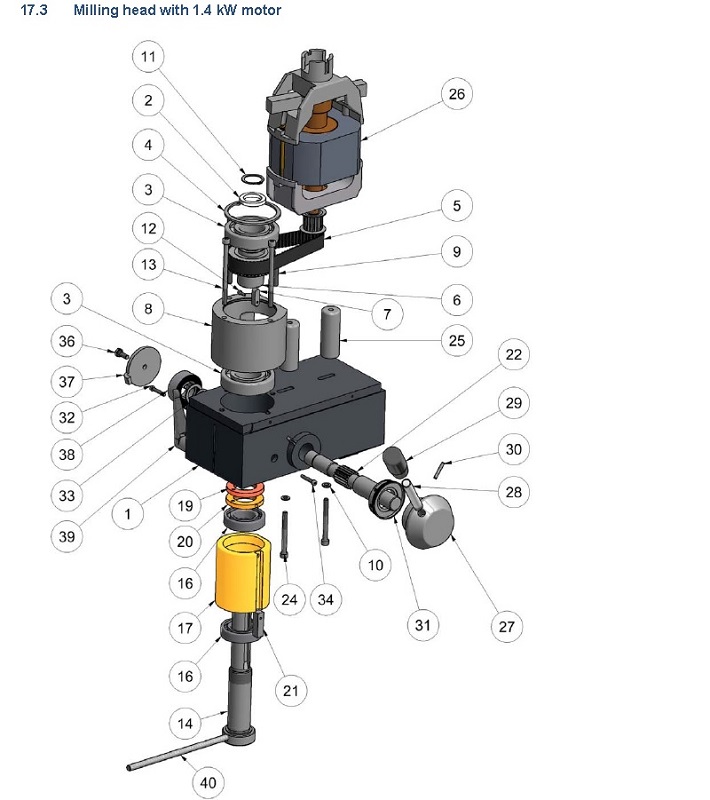

My machine had a Morse taper 2 spindle but I saw a Int. 30 spindle for sale on a German model engineering forum and I bought it, when changing the spindle I also took the opportunity to change the spindle bearings as the machine had done about 700 hours work on quite nasty and tough stainless steel. Interestingly the 2 Hp motor drives the spindle via a toothed belt but the belt puts no strain on the spindle bearings as the belt drives a pulley that is held in two large bearings

(item 8 in attached image) through which the spindle is a loose fit into and is supported by separate bearings and driven by a key slot. Other mill heads may also be done this way of course.

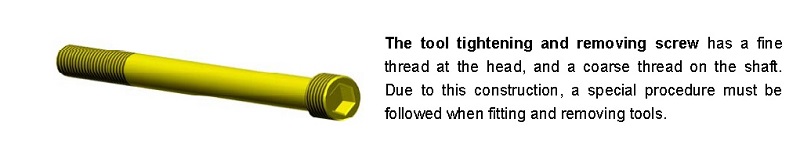

The spindle has a really nice tool release system which is a draw bar that has two different pitch metric threads, and the pitch difference very effectively jacks the tool out of the spindle, so no nasty hammering on the end of draw bars!!

The spindle has a really nice tool release system which is a draw bar that has two different pitch metric threads, and the pitch difference very effectively jacks the tool out of the spindle, so no nasty hammering on the end of draw bars!!

Exhaust stubs for OS60 Control Line speed engine, Turning done on EMCO Compact 5 milling on Wabeco CC-F1210

Exhaust stubs for OS60 Control Line speed engine, Turning done on EMCO Compact 5 milling on Wabeco CC-F1210 Crankcase pressure tapping, turning and thread cutting on EMCO Compact 5, hex milling on Wabeco CC-F1210

Crankcase pressure tapping, turning and thread cutting on EMCO Compact 5, hex milling on Wabeco CC-F1210

Carbon fibre parts for Americas Cup yacht machined on Wabeco CC-F1210

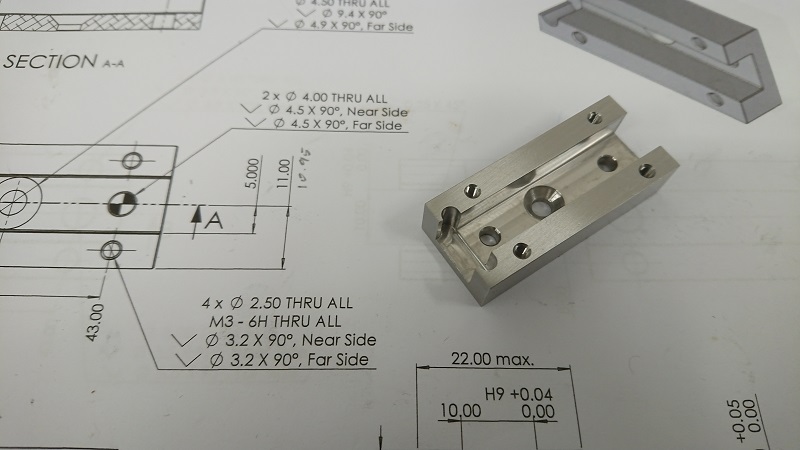

Carbon fibre parts for Americas Cup yacht machined on Wabeco CC-F1210 Stainless steel mould tool insert for UAV wing tool made on Wabeco CC-F1210

Stainless steel mould tool insert for UAV wing tool made on Wabeco CC-F1210So overall a quite interesting and useful machine that certainly can do accurate and predictable work, it also comes supplied with an inspection report and is intended for full time working in a light industrial or serious hobby environment, no caveats about hobby use only.

The acid test with a purchase like this is would you buy the same again? Well I am not intending on buying another mill and this one shows no signs of wearing out any time soon, but I will be buying a Wabeco 6000 CNC lathe as a semi retirement present to myself at some time in the near future so I think you can see that I am pretty happy with the machine.

Baz