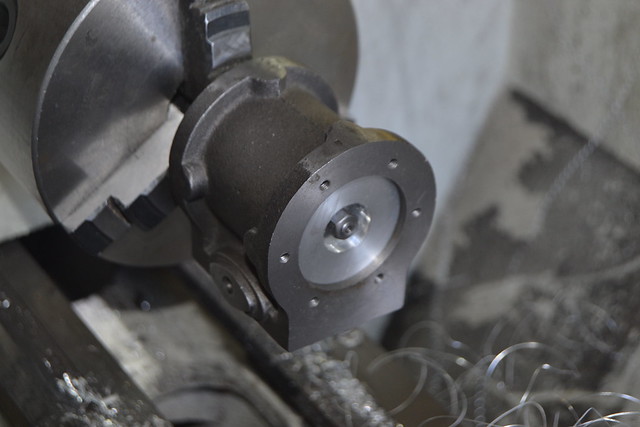

Although the no4 bearing blocks still need a bit more cosmetic work I decided to tackle the bottom cylinder cover and piston next. I did take a few photos of machining the cover but somehow seem to have deleted them before uploading to Flickr. Anyway it was a simple turning job from a casting I bought followed by cutting a M12 fine thread to accept the gland nut.

The 2 taps and the die I bought for the job were only cheap ones (I think I paid about £11) but I was quite impressed by look and feel of them and they did the job :-)

Although this thread is aimed at beginners it's difficult to know how much detail to show and when to be brief, I guess most beginners can turn a piston but I did take a few photo along the way. My initial intention was to make the piston from cast iron but after a bit of advice and a bit of thought I settled on aluminium. I've never used aluminium pistons before so we'll see how this performs on the hot stuff later but the lightness may be useful in high speed running ?

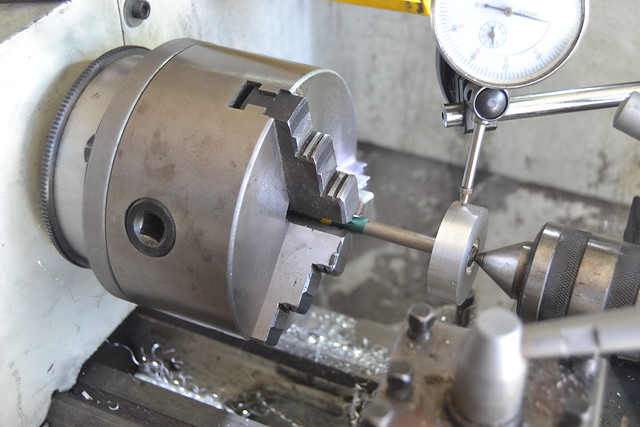

I like to turn the piston on the rod it will be coupled to, it is 7mm rod threaded at 2ba with a centre for stability.

Creeping up on the final diameter it's a nice close fit

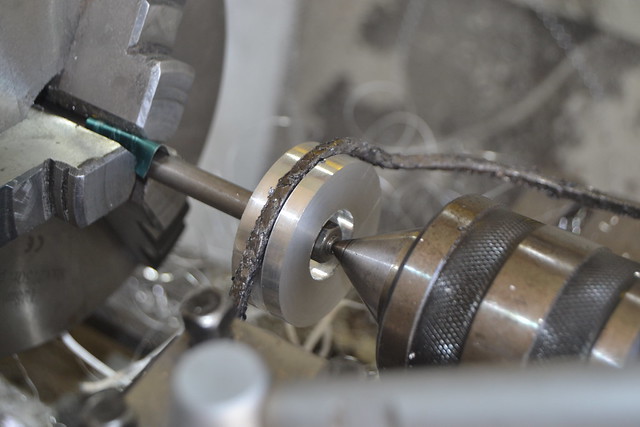

I think it may have been in Brians Oscillator build thread that the subject of graphite yarn piston rings briefly came up so for the benefit of those who have never tried it this is how I do it. The yarn for this piston is

1/

8" sq so with a parting tool I just gradually cut a piston groove until the yarn will just fit width ways but to a depth that it sits wider than the diameter very slightly.

Here I am getting close to the size of groove I want

A bit deeper then cut to length and this looks about right

Soaking the yarn in oil and packing it down it's possible to get a good seal around the piston, the ring is in place here and a couple of loose strands / graphite can be seen. It is a good seal though and slides smoothly in the bore

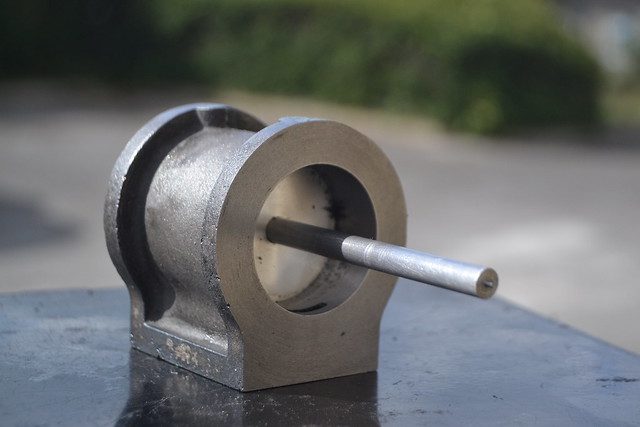

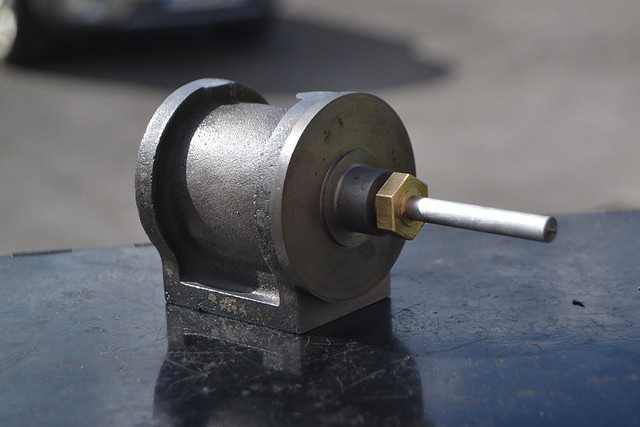

I'm now at this stage

With the covers in place I'm happy with the suction effect so hopefully the finished engine will have a bit of oomph