Hi

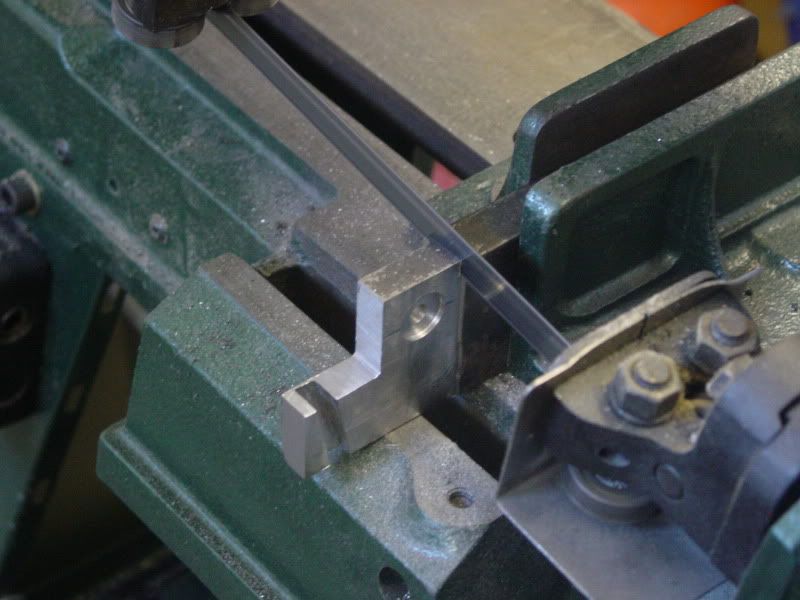

Making the tool holder proved to be a bit more of a challenge. I didn't have anything large enough to get the whole thing in one piece so I had to fabricate it. A square is cut out of one corner of a bit of 15mm thick steel.

Then set up in a similar fashion to the grinding jig, all angles are 12?.

Then cut a 1/4" wide slot.

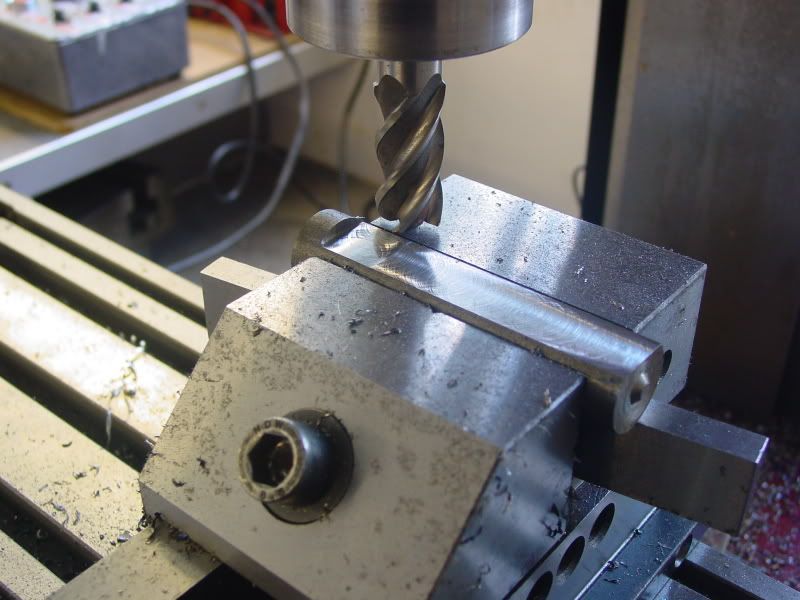

a 6mm hole is drill followed bi a 5/8" cutter.

Then part from the parent material

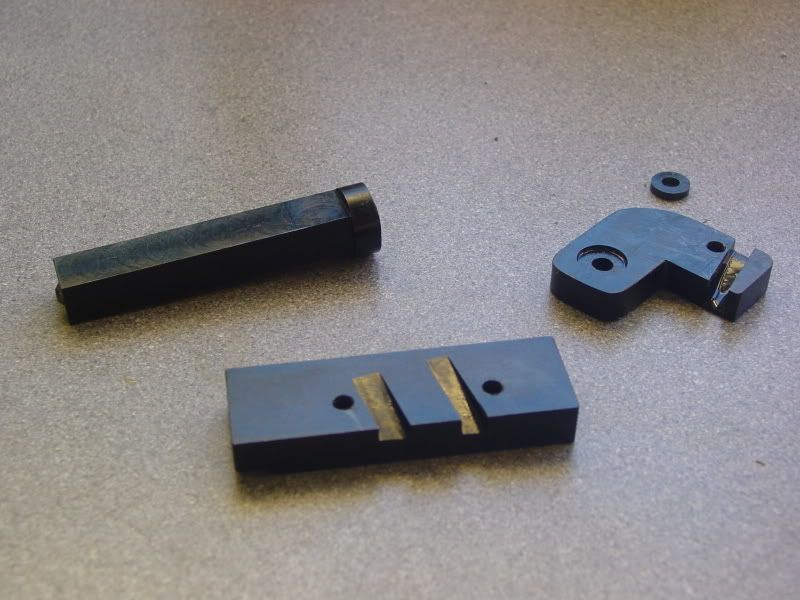

Drill and tap 6mm some round steel bar and turn a spigot to be a tight fit in the recess machined in the other part.

Machine flats on 3 sides of the round steel bar

A trial assembly

Drill and tap 6mm close to the 1/4" slot to clamp the tool steel in position. I fettled the parts abit, removing corners and sharp edges etc then then blacked all the parts.

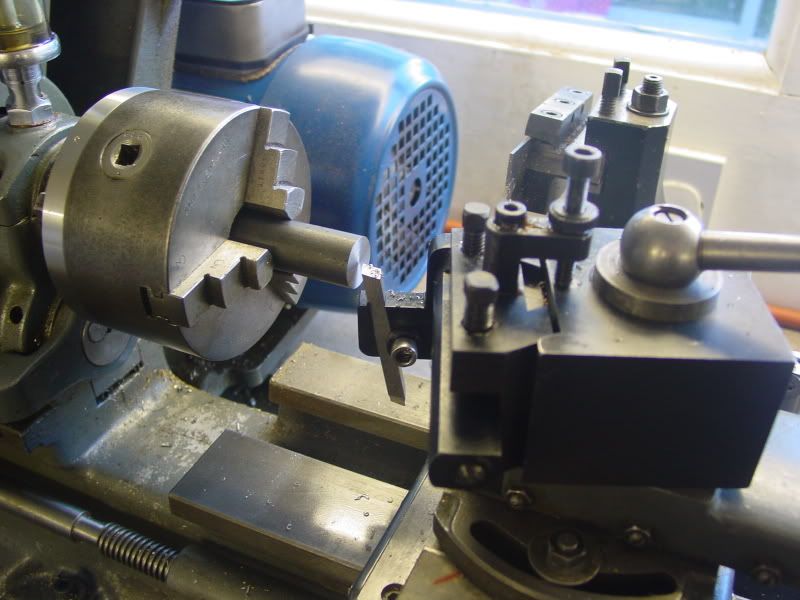

I can adjust the tool by turning the tool post itself and it will also turn where it is fixed together at the spigot.

After clamping the tool in the tool post I set the point of the tool steel to centre height and tightened the clamp.

The tool works beautifully, much better than I expected really.

To face the end of a work piece I just swing the tool post round a bit.

Here's a short video of the tool in action.

Cheers

Rich