Next on the list was the conrod, this is made from a 9" length of 5/8 x 1 1/4 flat steel

When this was cut I thought that while I was setting up the machines for the conrod that I may as well do all the other similar rods in one go so also cut some steel for the two eccentric rods, pump rod and two tie rods

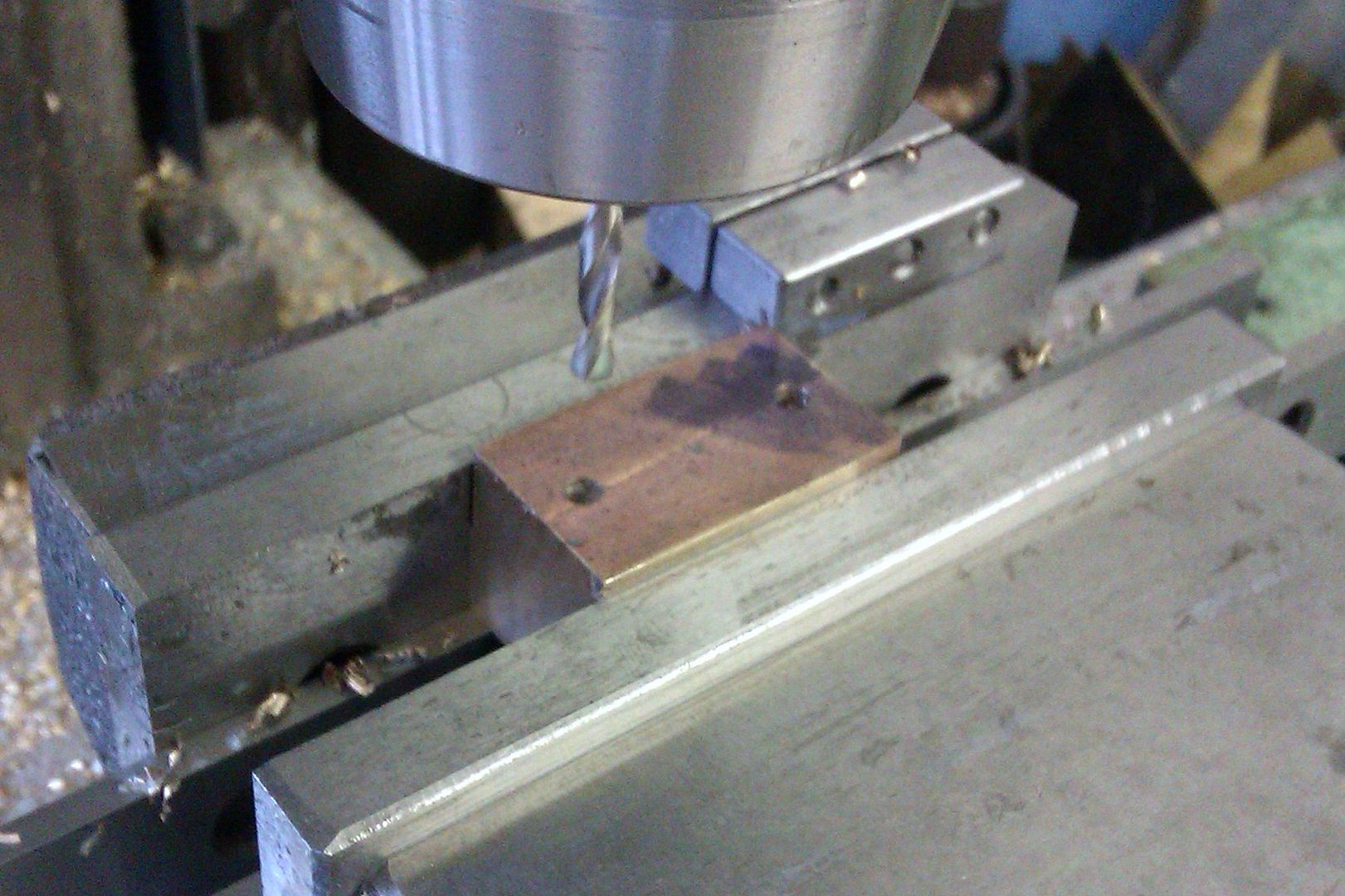

After squaring off the ends to length each bar was held on end and the two bolt clearance holes drilled together with a small centre hole formed with a BS 0 centre drill

Each bar in turn was then held in the 4-jaw with tailstock support to reduce the majority to a cylinder followed by adding a slight taper to each end for about 1/3 of the length

The tapers were then blended by hand to give the traditional fish bellied shape

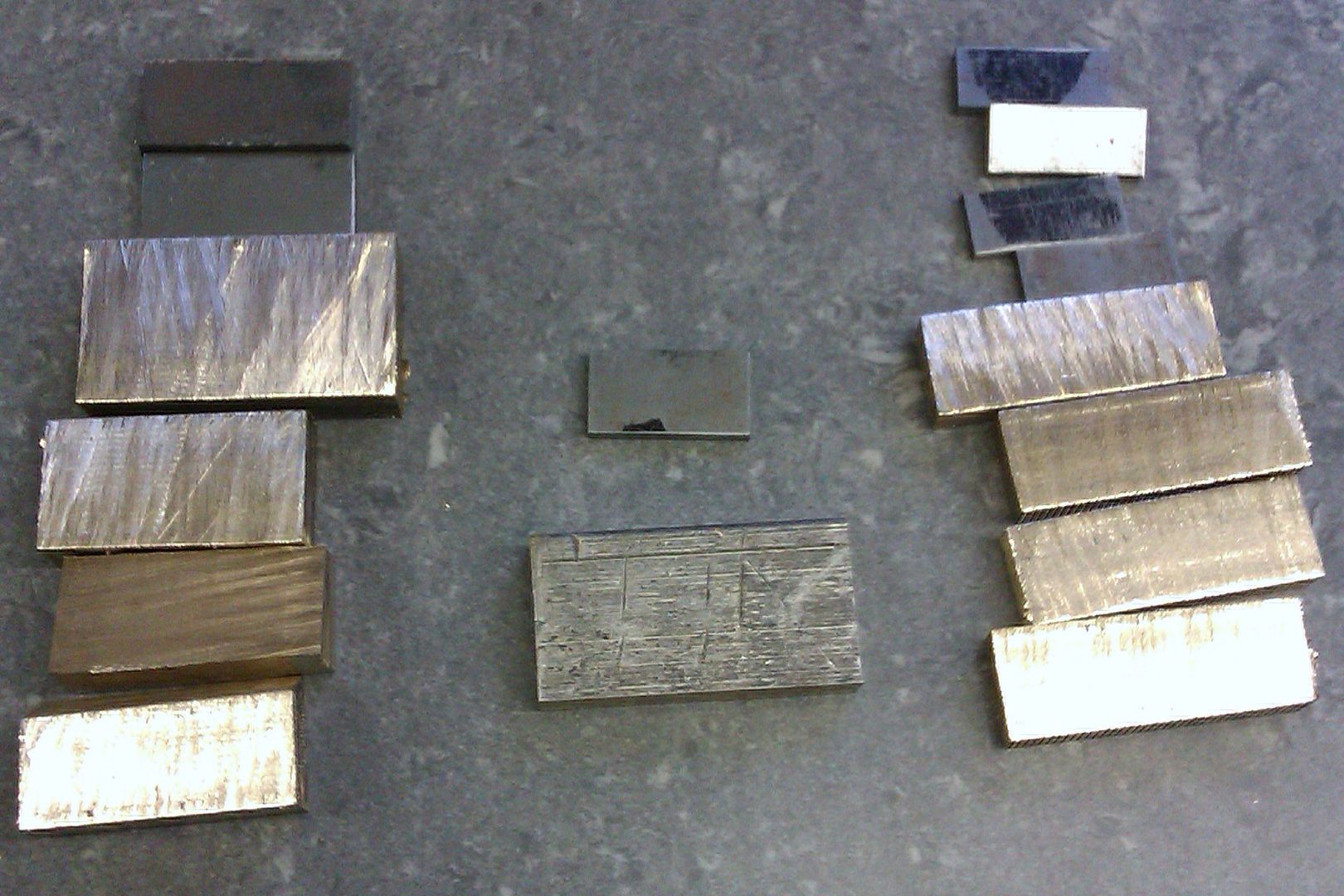

I then set the rods to one side and cut some bronze and steel for the bearings and end caps

The bronze was then machined to thickness with a flycutter

Before being tinned with soft solder prior to being sweated together

The bearings were then flycut down to the finished sizes

Then set up a stop on the mill vice so the bearings and plates can be drilled for the bolts

And here they all are ready for assembly

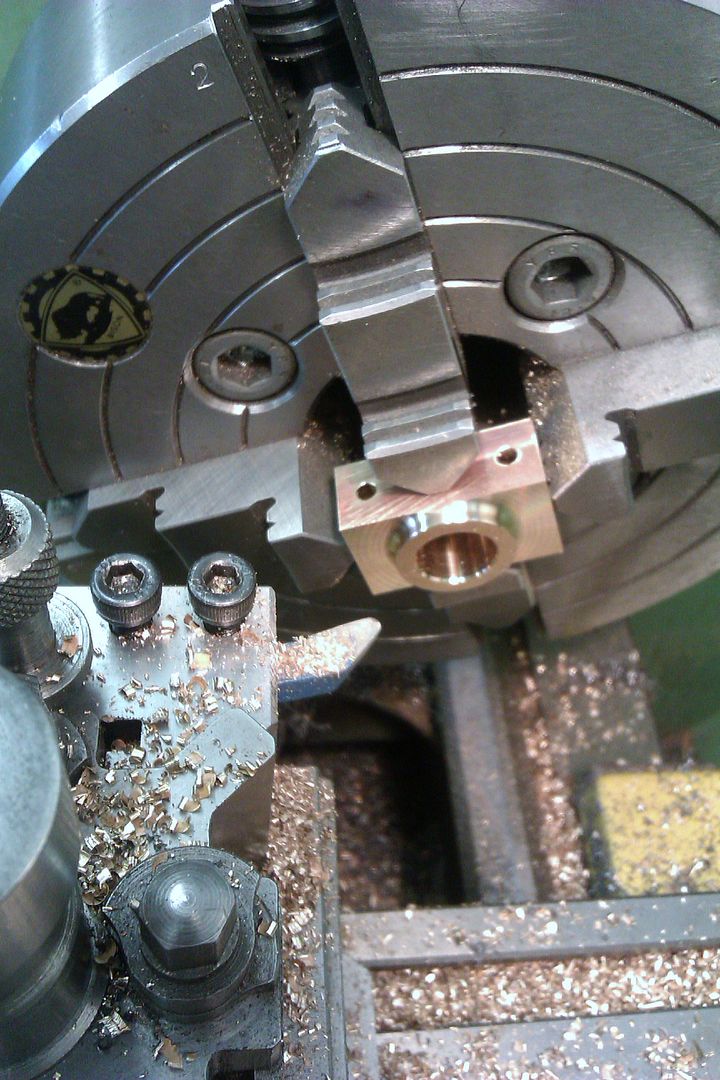

Well actually the bearings were bored first and the widths reduced to leave a raised section around the bore

With then now assembled the narrow edges could be turned and recessed

Must be doing something right as the two tie rods seem to have ended up the same length

And them all completed

Well I said it wass going to be a long one, so will the flywheel thats comming next.

J