The Alliterative Engine

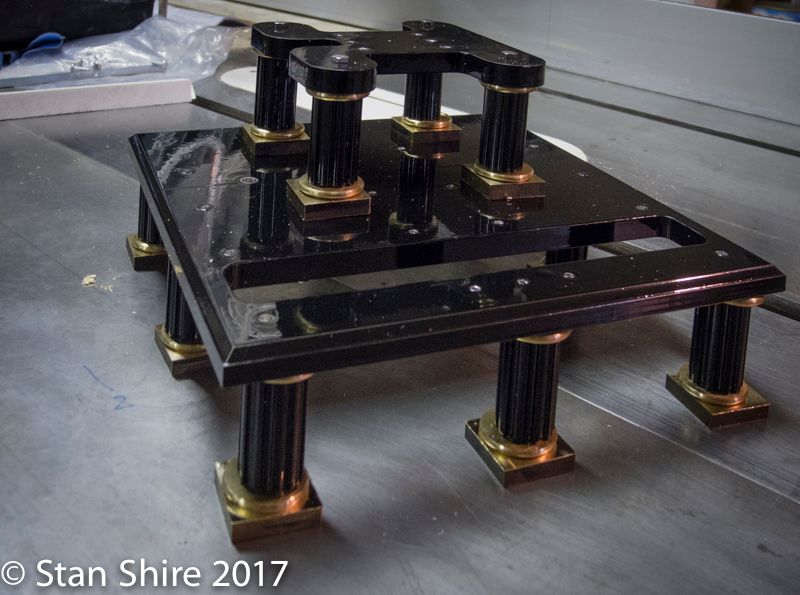

Simpson and Shipton Short StrokeEpisode 3With the plates completed, I wanted to get on the columns, the bases and the rotunds.

There are 12 fluted columns, 12 bases and 24 rotunds to make,

First up, the fluted columns. My first thought was to setup the dividing head on the Bridgeport.

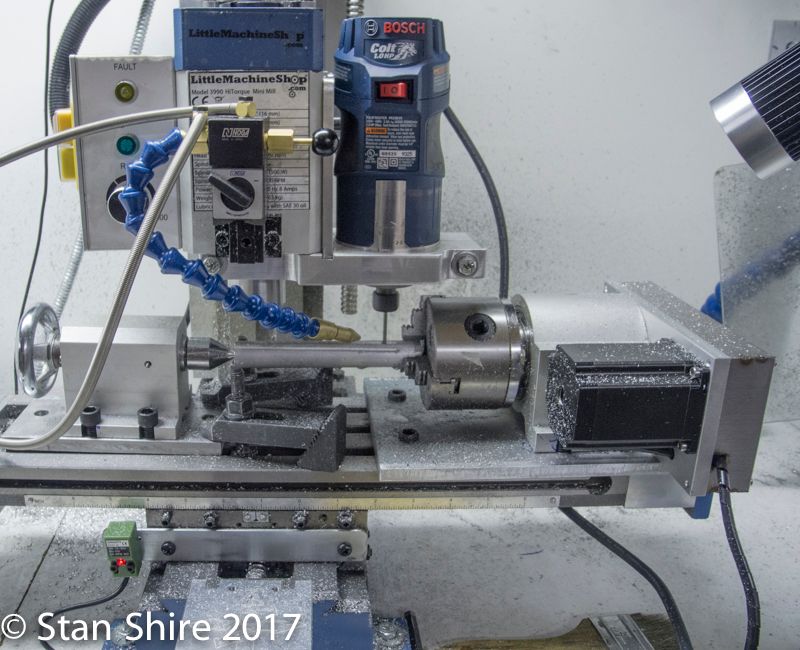

On second thought, this seemed like a good opportunity to sort out the CNC rotary axis.

Setting the steps per degree in Mach 4 took quite a long time until I got it bang on and then indicated.

After that, not much to do but watch it make 4, 6” long columns.

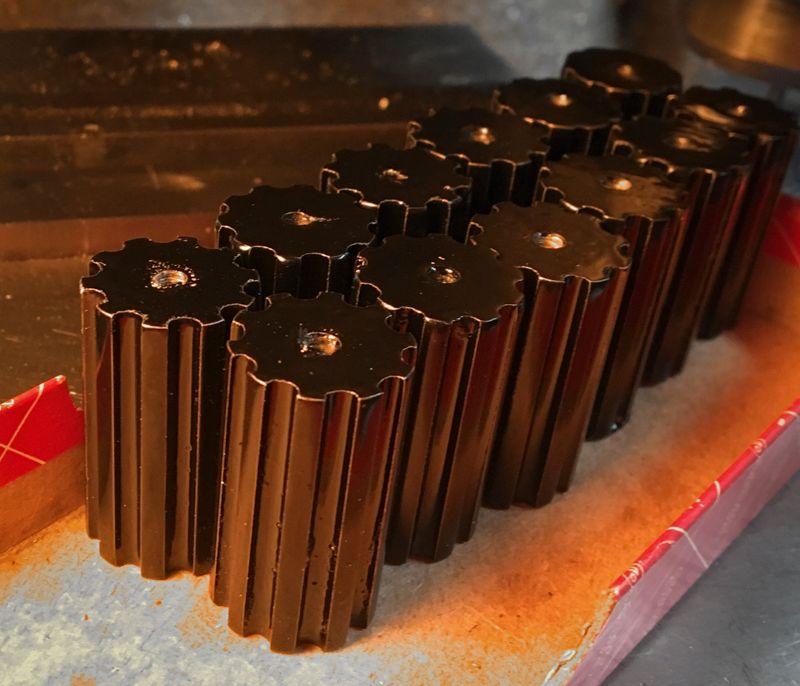

These were later parted into the 12 columns on the lathe and powder coated. In addition, each column is drilled and tapped 6-32 ate both ends.

The Rotunds

The RotundsThe rotunds are made with a form tool. I began with a piece of tool steel and milled a semi-circle into one end. Using a tapered cutter give a nice relief angle to the hole.

To create the relief angle, on the front edge, I used the surface grinder and sine vise.

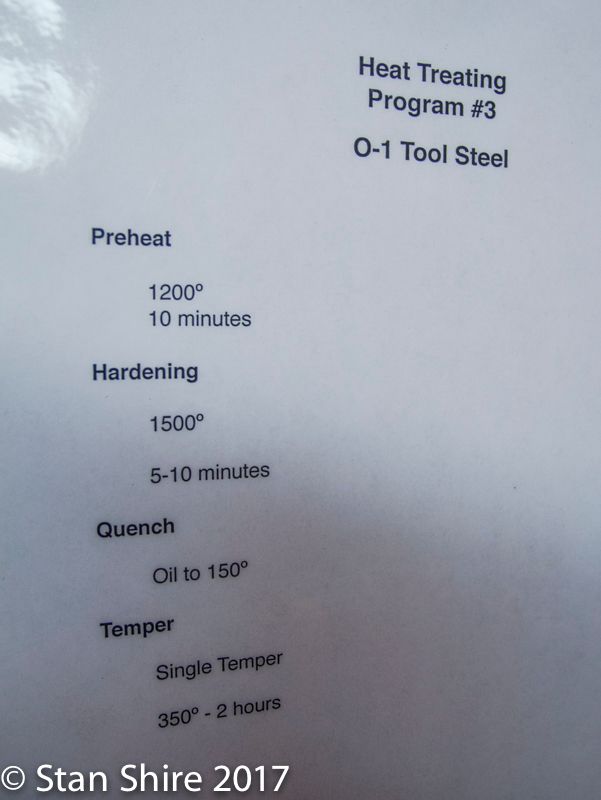

The tool was heat treated and then diamond honed.

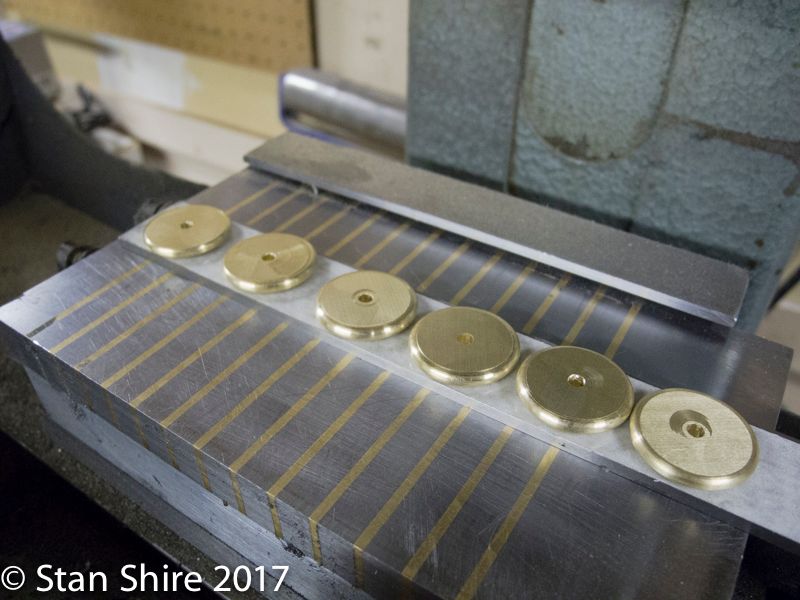

On the lathe, 24 rotunds were turned.

It’s quite important that the columns, the bases and the rotunds are the same height. If not, the plates will rock, twist and other bad things.

First, each of the 24 rotunds went into a 5C collet on the surface grinder and, on the recommendation of Norton, a black silicon carbide wheel was installed to machine the brass. With the mini-cool running, the wheel did not load up and gave a very nice surface finish.

So, one side flat. The reverse was done in groups with the rotunds fixed to a ground flat with double-stick tape. All 24 were within .0005. My backup plan, if the coolant was causing the tape to fail, was

The bases were cut from a 1” brass square bar. I wasn’t happy with the thought of parting them off on the lathe or the bandsaw as I’d turn as much of the brass into chips as the part thickness. My solution was to face them on the Bridgeport and use a thin slitting saw.

One face was flattened with the face mill and then the final dimensioning was the same as the rotunds: double-stick tape and surface grinder.

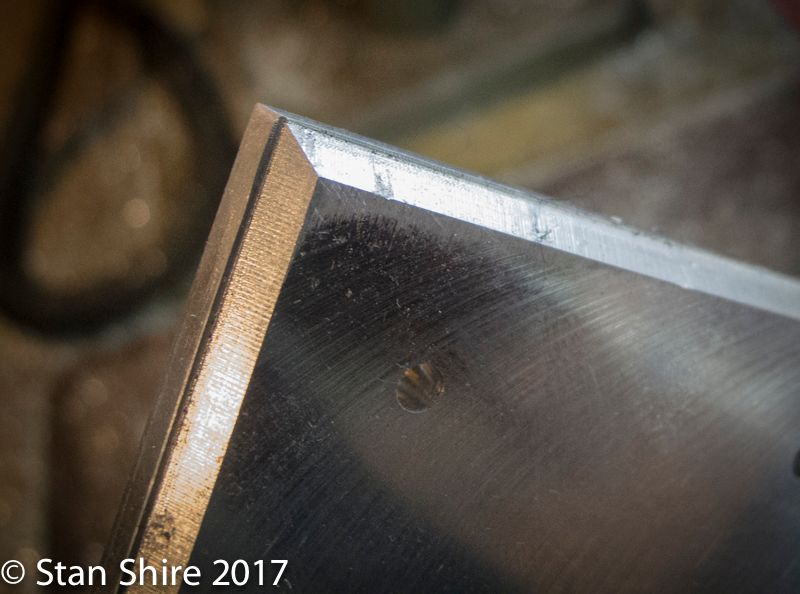

Returning to the plates, I neglected to show the pre-powder coat finishing.

Flattening

Chamfering

Finally, the obligatory family shot.

Thanks for watching.