I've now managed to complete the valve chest, making it is simply an exercise in drilling , drilling and more drilling but as this thread is likely to be of more interest to beginners I'll post an update for the benefit of anyone else who may want to make this engine.

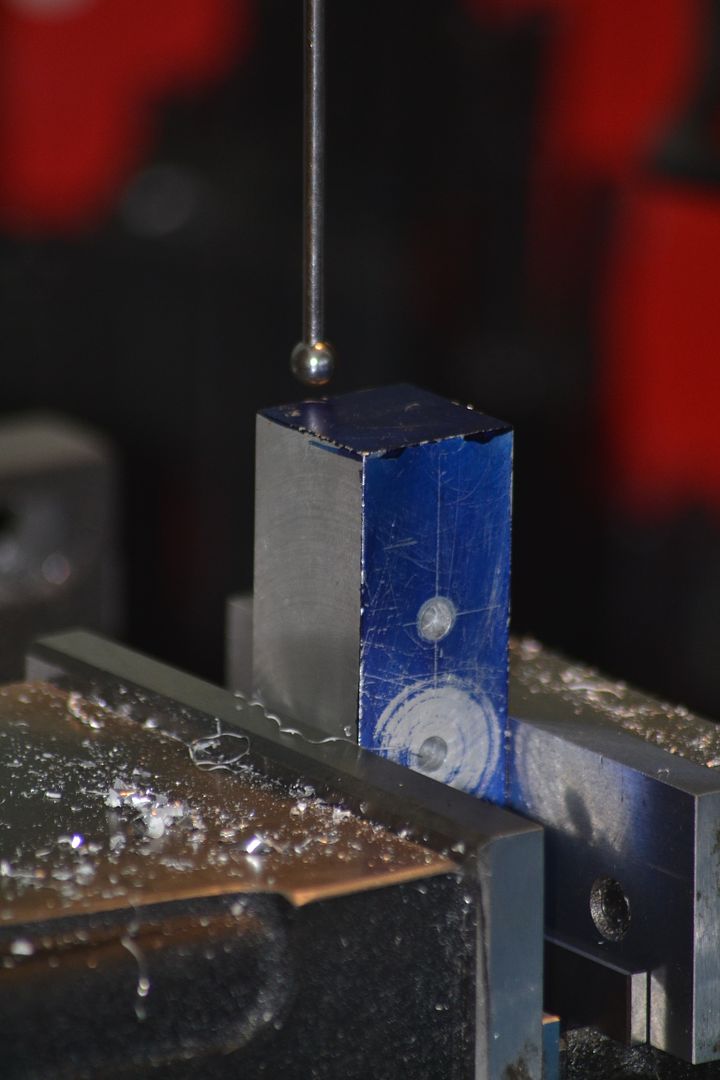

The valve chest is a 24mm square aluminium block 66 mm long, the first photo shows 2 6mm dia holes drilled to meet will the cylinder holes and about to drill a full length hole of 9mm dia to take the spool valve. I've never used a wiggler edge finder before but this seemed a good opportunity to try it in order to get the hole 9.5mm from the rear edge. (it may be worth mentioning to any other newbies wanting to build this engine that the spool bore isn't central in the chest but is offset in 1 axis.)

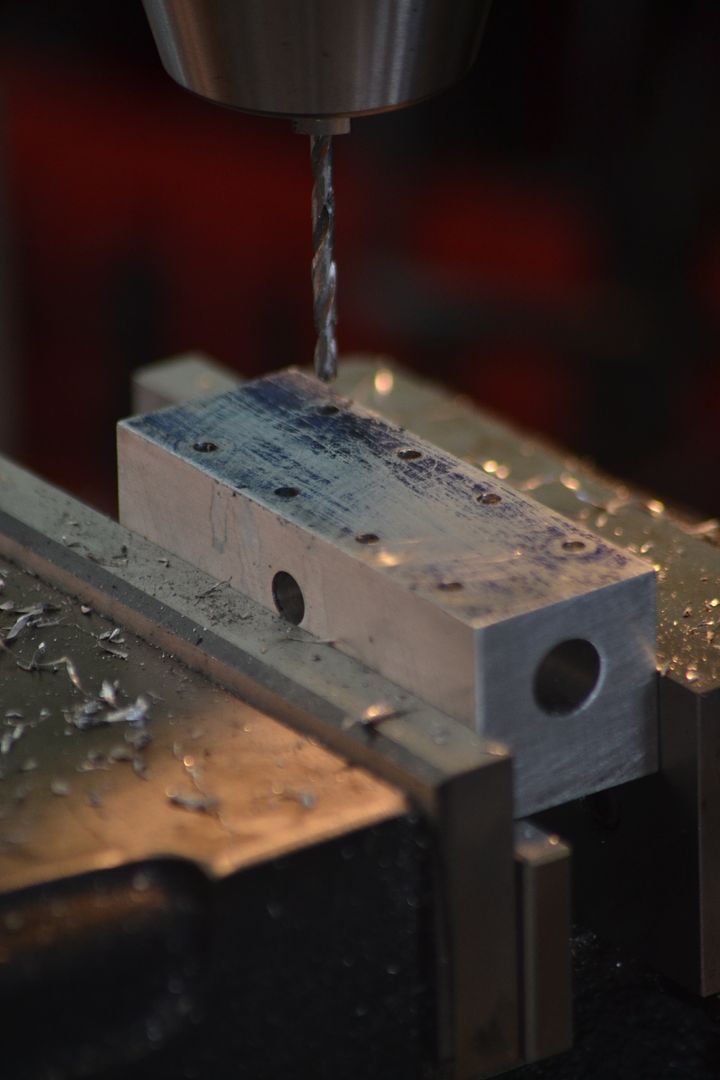

Looks to be running true and swarf is coming out where it should.

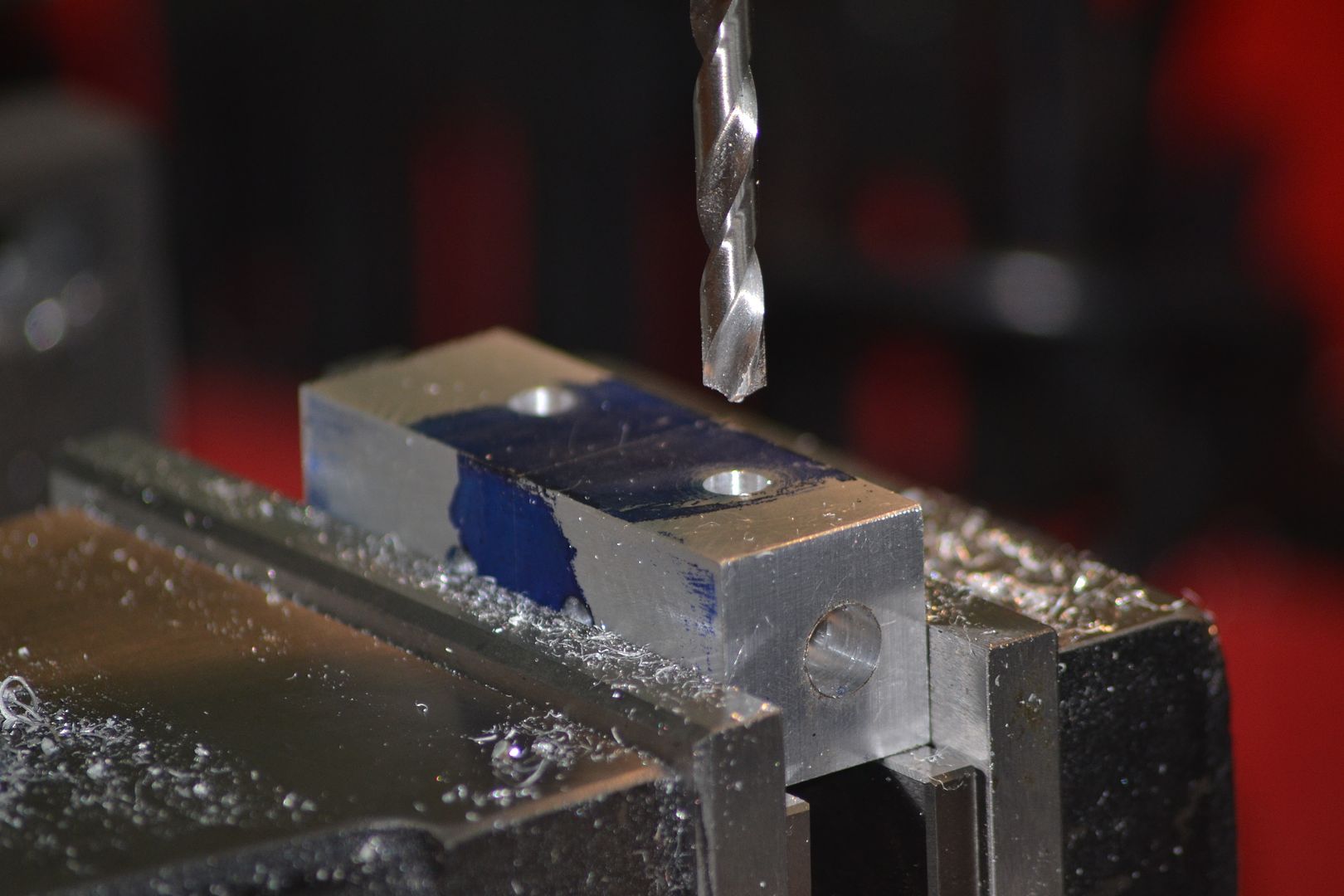

2 more 6mm dia holes are drilled to meet the central bore these will form the exhaust - another single hole is drilled on the opposite face to form the inlet.

The inlet hole can be seen in this photo as I drill the 8 securing holes.

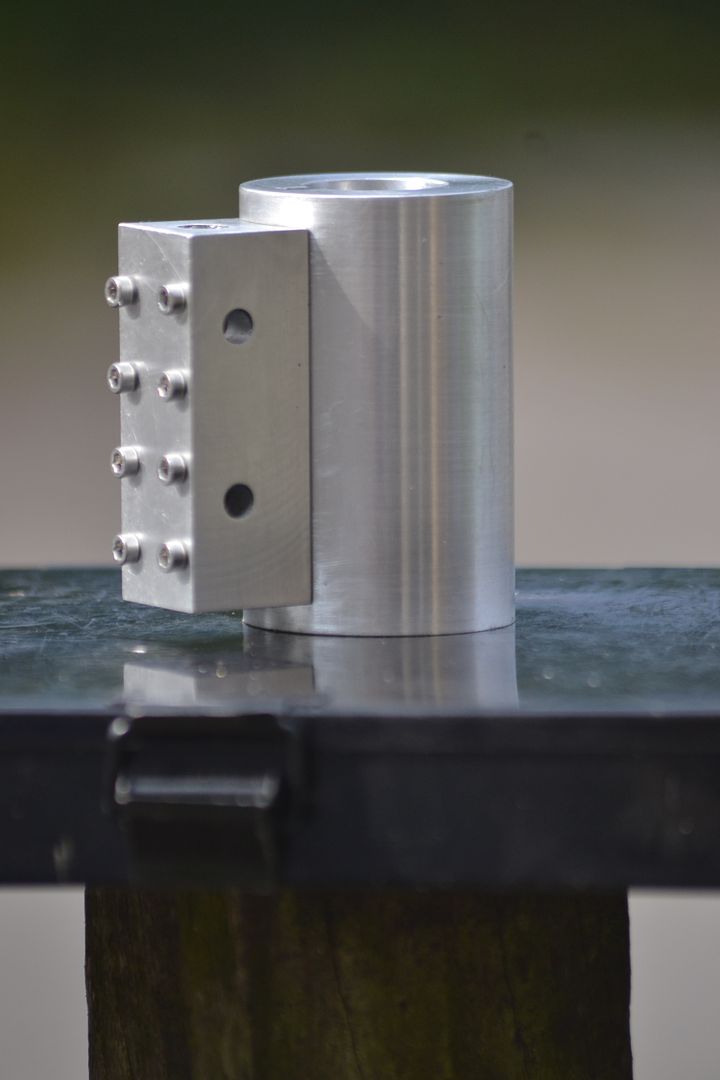

I wasn't really sure of the best way of getting the cylinder holes and valve chest holes to line up exactly - I had used the hand dials on the mill to drill the holes in the chest exactly evenly spaced and possibly could have adopted the same method on the cylinder but decided I'd drill the cylinder with the chest in place.

Lining the chest up against the side of the drill bit and ensuring it is seated flat on the cylinder I drilled 1 hole in the cylinder then removed everything tapped the cylinder at 3mm before bolting the 2 parts together and repeating to get a 2nd bolt in place. With 2 bolts holding the chest in place I drilled the remaining 6 holes.

Maybe it was a bit of an amateurish way of going about it but the result turned out well.

That's enough drilling for today, now off to get myself a few cans of the amber stuff - maybe will do the cylinder end covers tomorrow depending on the severity of the forthcoming hangover

Peter.