Hi

Its been a while since I posted anything, tis the season of DIY

and a short holiday so my projects have taken a back seat. The portable steam engine, the bending rolls and the tumbler polisher are sitting there patiently waiting. However another topic took my interest so I have been experimenting in the odd half hour here and there.

Just before we get into it let me show you something else that is sort of related. One of my other passions is woodworking, and I love using hand tools. There is nothing quite like a well honed chisel or a finely set plane and a nice piece of hard wood. Anyway at a recent steam fair I came across an old rapier plane. Unfortunately it had a piece missing, the blade clamp and also the 3 blades. After a brief discussion with the stall holder he graciously gave it me

happy days.

Back home a search on the internet soon yielded all the info needed. A picture was printed out. You can see the bit that was missing and the replacement part being hacked out of some steel bar

Steel is ok but it does rust easily so it will be zinc plated, which brings us nicely onto the topic.

The internet provided all the info for me to have a go.

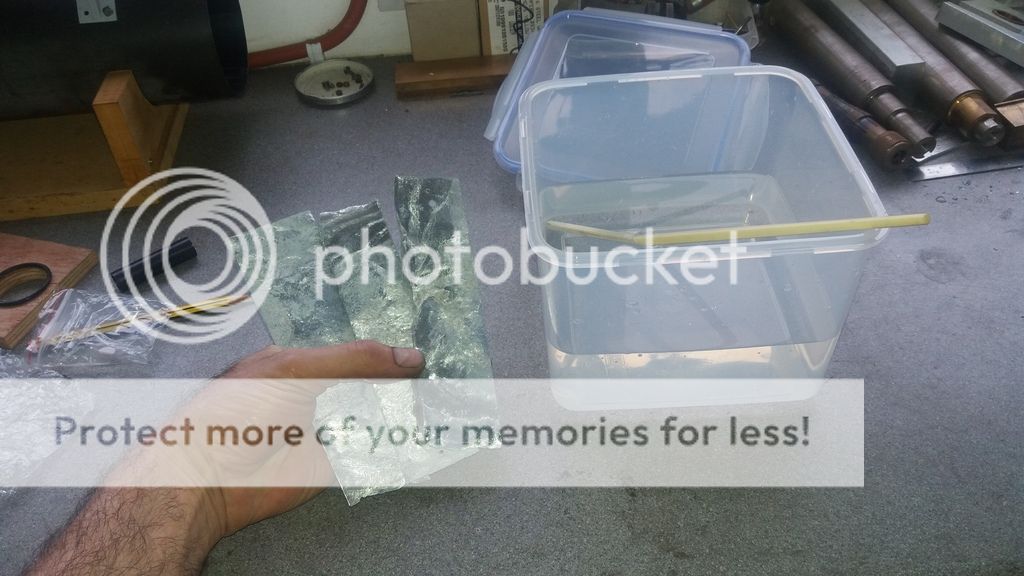

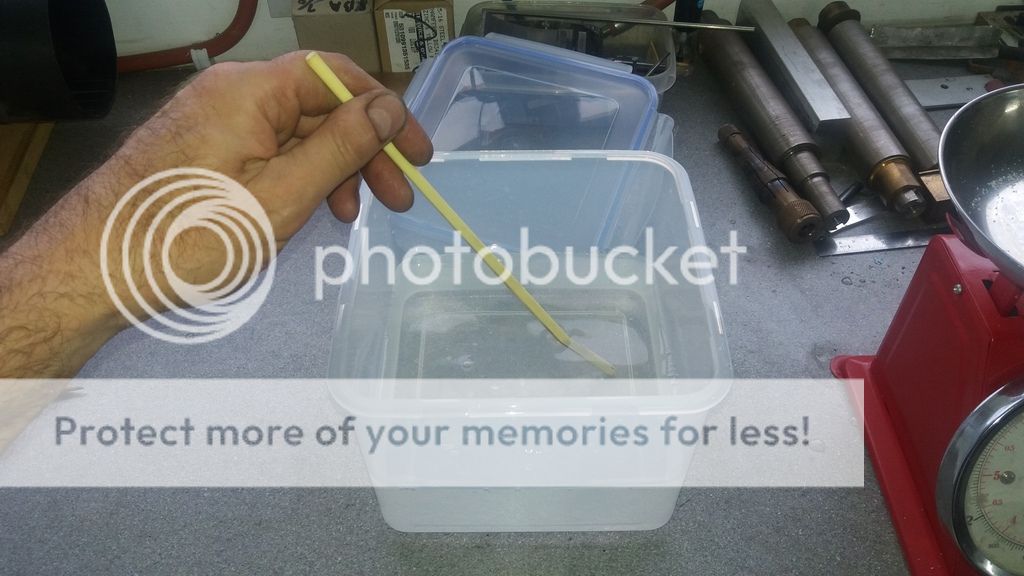

A plastic container (about 2.5ltrs) with a lid that seals and some white distilled vinegar

Sugar

Epsom salts

Zinc

Mix in the following quantities

1 liter of vinegar

100 grams of Epsom salt

120 grams of sugar

8-10 square inches of zinc

Vinegar is a mild acetic acid and slowly dissolves the zinc metal into solution.

Epsom salt is magnesium sulfate and is the electrolyte of the plating solution

Sugar is used as a brightener. It causes many smaller crystals to form on the surface instaed of fewer larger crystals

You will also need a low voltage power supply. Preferably one that can be adjusted from 0.5volts to about 3 volts. You might get away with using a 1.5 volt battery. I have a 12volt power supply in my workshop and also a voltage regulator that will take 12 or 24 volts in and give anything from 0.2 volts out.

Weigh out the epsom salt and sugar and add to the vinegar at room temperature and mix in

The container I used was big enough to double all the amounts to fill it.

Add the zinc pieces and leave lightly covered for 24 hours or so. You won't see any bubbling for a few hours but by the end of the next day you should see small bubbles coming off the zinc pieces. This is the zinc meta lbeing converted to soluble zinc acetate but does give off hydrogen gas so don't tightly seal the container as pressure might build up and rupture it. Once plating statrs the zinc anode will dissolve at the same rate that zinc is plating the cathode so the zinc solution should not weaken.

Ok, onto actually plating something. Cleanliness is the key. The plating will not stick to finger prints ,oil, dirt etc. Scrub the part and rinse well. Wear rubber gloves.

I used some old copper brake pipe across the top of the contaner and used copper wire to suspend the parts.

Make an Anode (+ terminal) of Zinc metal and attach the Cathode (- terminal) to the part to be plated.

If the solution has a sufficient amount of dissolved Zinc you should see the part start to turn Zinc coloured almost immediately

Aim to adjust the voltage so that a small amount of bubbling can be seen. If the voltage is too high you might get a slightly burned look and rough edges. If the voltage is too low the plating will take longer and might have a frosted look. Some experimentation is required

After 10 -15 minutes remove the part, don't forget your rubber gloves, give it a rinse and a light rub with a scotch bright pad to shine it up. If the plating looks a little thin stick it back in for another run. Apparently it is better to do several short runs than one long run

Finally the blade clamp from the plane

Thats about it. Polished chrome it ain't but gives an anti rust coating that should last. The chemicals used are fairly safe and can be handled without harm.

Hope this helps

Cheers

Rich