I'd say you are juggling two mant bits of metal at once.

Treat the top, bottom and bearing as 3 separate parts.

First soft solder the bearing halves together.

Now machine them to a length just over your turned dia, machine the caps to the same length and finally the bases to the finished length over the feet.

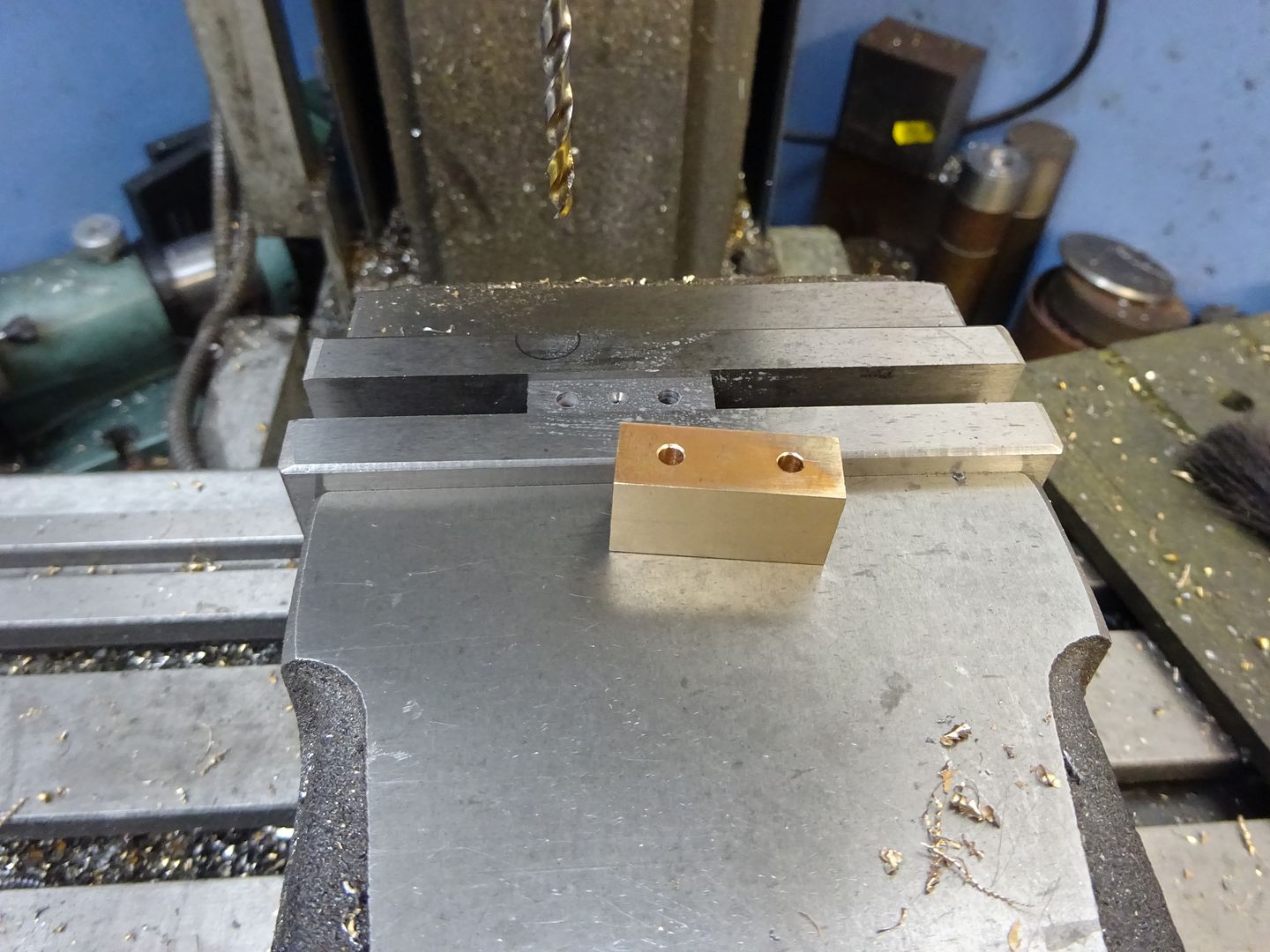

Now set up in the mill and drill clearance holes in the bearings and caps, note which side is against the vice fixed jaw and if you use some form of stop it will allow you to do the 4 caps and 4 bearings at equal settings. Add a small BS0 ctr drill hole to the middle of the bearing caps as you do them.

Now drill and tap the bases and also put in the holes for the feet.

The bearing can then be lightly held in teh 4-jaw to be drilled & reamed

With that done assembe the three partsand screw together making sure that the faces you had against the vice fixed jaw are all on the same side.

Set up in the 4 jaw with packing behind to give a level surface to rest the base against, and set the ctr drilled hole to run true. Bring up the tailstock centre for support, remove packing and turn your outer curved surface, this is a longer part but same setup.

The ctr drille dhole can now be extended with a 1/16" drill so it breaks through the top bearing half for oiling. Mark all 4 bits of metal so they go back together the same way before taking apart to deburr and melt the solder apart

You will just have the base rather than a conrod