Gosh - it's been almost a month since any update on this thread ... it must be motorcycle season

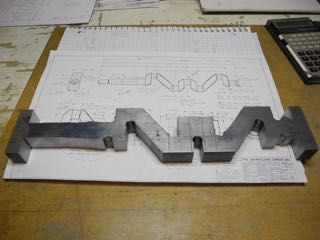

I've made some progress on the crankshaft though. It started with a piece of annealed 4140 that was available in flat stock of the right dimensions. That saved some work compared to starting with full round 1144. So, after a layout session and some time for the subconscious to double check for any errors it was time to drill some holes and cut off some extra bits.

I then setup the blank on the mill using a vertically mounted rotary table and tailstock. I wanted to try the technique of milling off the square corners to avoid as much interrupted cutting as possible. It worked fine but I'm not sure the bother of setting it all up was worth it. I suppose one would have to do two cranks, one each way, to really know. In any event, it made setting the journal spacing easy.

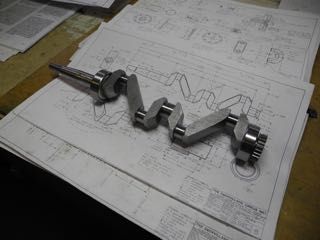

You might just make out a centre fixture I'd made for use on the driven end of the crank. It was from an Model Engine Builder article and I am happy with how secure it held the end of the crank and made changing centre easy and secure. Here the crankshaft to be is in the lathe having the journals cut and "webs" cleaned up.

The journals polished up nicely with some emery and then wet/dry. Even got them all within 1/4 thou of each other (near as I can measure anyway.

Once all the between centres work was done on the journals it was time for that irreversible step of "cutting off the ears". I did the prop end first so I could still drive the crank using the fixture. Supported the end with a fixed steady to cut the threads and taper. Then the "back end" was cut off, cleaned up and drilled for the cam drive gear screw and shoulder.

After all was said and done, the bearings and the gear slipped on with just the right amount of resistance. Pleased about that. (Reminds me of a flying instructor from years ago ... "trust your instruments", he'd say)

While fiddling with crankshaft bits, might as well do the prop hub and washer.

... and they fit too!

Now that I've caught up with these photos, next up will be the cylinders. I've roughed out a mandrel to hold them while turning the external features. I'll finish sizing the mandrel once I bore all the blanks to size (slitting it seemed to have relieved a little bit of stress in the material). Here's hoping I can get all four cylinders to the same size; within reasonable limits of course.

Until next time.

Charlie