I got pics. You asked (yelled at me for them) so no complaining of what you get.

Really didn't manage a lot today. And I wanted to do something a little less stressful.

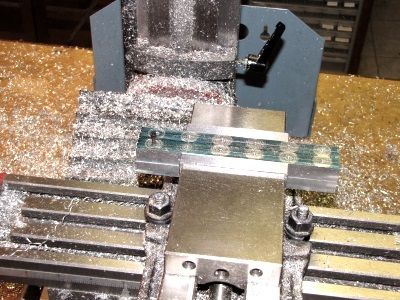

So I worked on the plates that sit on top of the frame. The cylinders will sit on one of them.

Both are there. Each takes 6 bolts front and back.

Then I squared up some blanks for the front bearings. The right one is sitting on the blank that would hold it.

The thing is...those bearing blocks are kind of 'L' shaped. And the drawings have a fillet at the inside corner of the 'L'.

Not that it's necessary but I think it would look better. Just not sure how.

I'm thinking of roughing out with an end mill and then taking a ball end mill to make the fillet.

Not sure if that's right or how it would work and not get bad machining marks.

Unless I get alternatives I'll practice on the part in the waste area.

On another note...

It looks like my hope for a new mill and/or lathe this spring is dashed.

Wedding, T laid off, new roof, new chimney, repair from storm damage.

And now today...pool cover developed huge hole and fence is down.

Well, we all have our crap to deal with. No sense you having to listen to mine.

There's always a silver lining by the way.

I'll let you know when I find it.

(There's always family, health, fine friends, and the fun I get being a class clown and poking at you all.)