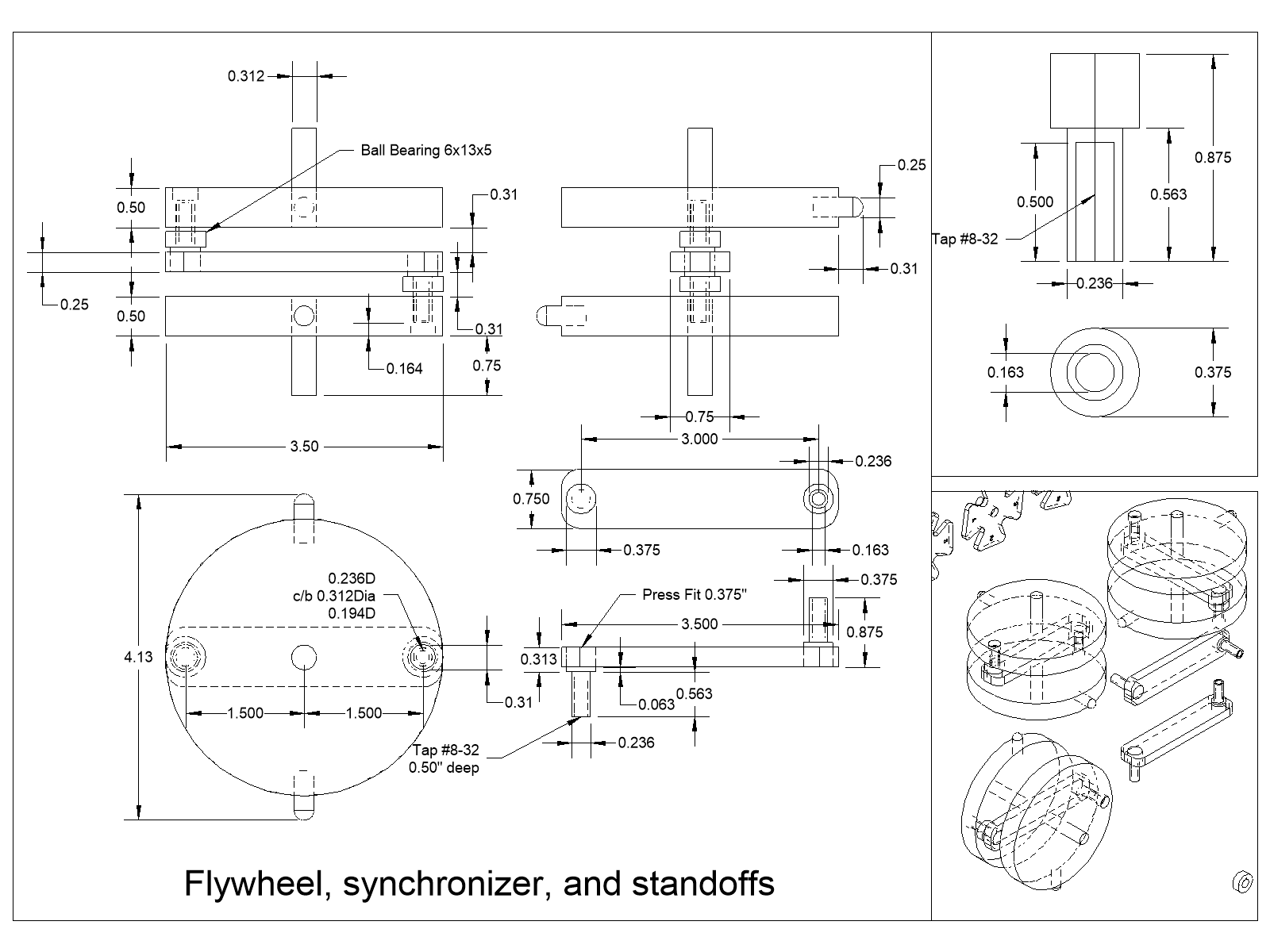

While I figure out the "plumbing", I am working on the details of the flywheel assembly. There are two 3.5" 1/2" thick aluminum disks with crankpins on opposite sides and a synchronizing bar connecting the pins:

I am trying to use some 3/8" O-1 tool steel drill rod for the standoff shown in the upper right. It should be a press fit into the 3/8" hole in the synchronizer bar, but the hole is a little too large. I could remake the piece (actually I am trying to salvage the piece I made for the previous design), but I might be able to use a chisel to make some knurl marks on the surface to make it fit tightly enough. I might also use some Loc-Tite.

Another idea I had was to tap the holes for 1/8-27 NPT and make mating threads on the standoff. That would make a tight joint, but it may be difficult to get the right depth.

The turned-down section is made for a 6x13x5 mm ball bearing, and it then should be a tight fit into the flywheel, where it will be secured with a #8-32 SHCS. The ball bearing will be pressed into the connecting rods, so it will become a fixed assembly not designed to be disassembled, although it could be. I may be able to add a setscrew in the flywheel to keep the standoff from twisting once it has been assembled and adjusted. From my experience with the previous design, the alignment is rather critical. I really don't know how much torque will be exerted on the joints - hopefully not too much.

I have started to turn down one of the standoffs, and it seems a bit difficult to get a good finish with a HSS lathe bit. I may experiment a bit with regrinding the tool and trying higher speed. Any suggestions on machining O-1 steel? Or perhaps I should use another material? I have 416 SS, 360 brass, and 1045 steel rod.

Here is some information non machining tool steel:

http://www.simplytoolsteel.com/machining-tool-steel.htmlhttp://buffaloprecision.com/data_sheets/DSO1TSbpp.pdfhttp://en.wikipedia.org/wiki/Tool_steel