Hi

I have decided to modify the power feed. The smaller electric window motor works ok but is about at its limit so I am changing it to a more powerful wiper motor and I am upping the gear ratio from 2 - 1 to 3 - 1 to speed things up a bit. The existing gears are 40 tooth on the motor and 20 tooth on the lead screw. I am going to change the 40 tooth on the motor to a 60 tooth. As mentioned above I cut these gears myself so I thought I would show you how I do it. I normally cut 2 or 3 gears at once to save time and helps keep a few in stock but I only had enough material to do the one today.

After roughing out the blank from 10mm ally plate its held in the chuck and bored.

Turn a mandrel, drill and tap the end 8mm

Fit a heavy washer

Followed by the blank

And another heavy washer and 8mm cap head bolt to lock the blank securely to the mandrel

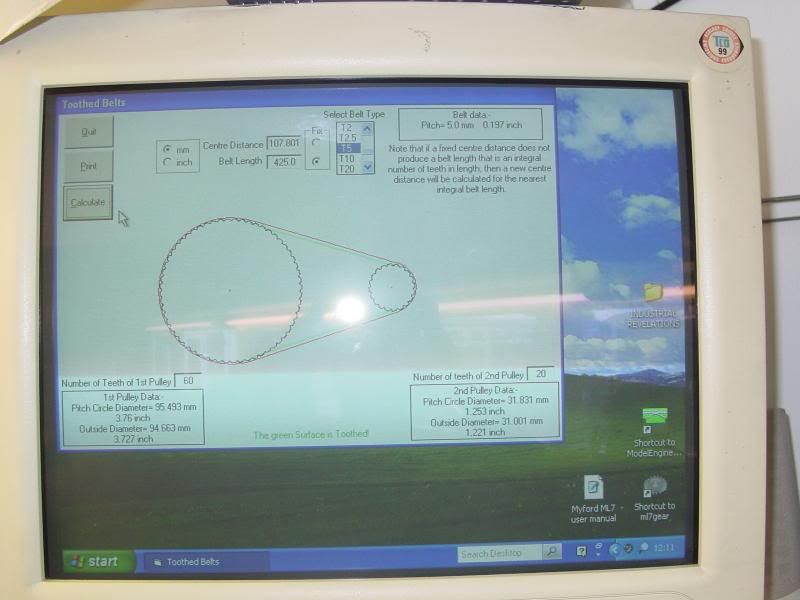

I use this great free little programme called model engineers utilities, you can get it from the following link,

http://www.colinusher.info/Software/Model%20Engineers%20Utilities.html to calculate the blank size.

Then turn the blank to size

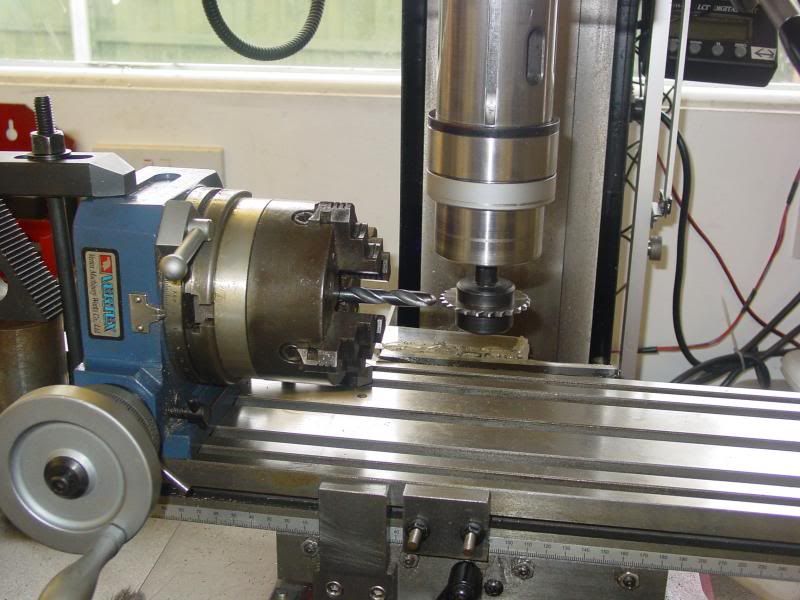

The rotary table in the vertical position with a 2MT drill in the the 2MT socket in the rotary table to align the cutter on centre height.

The first few teeth cut.

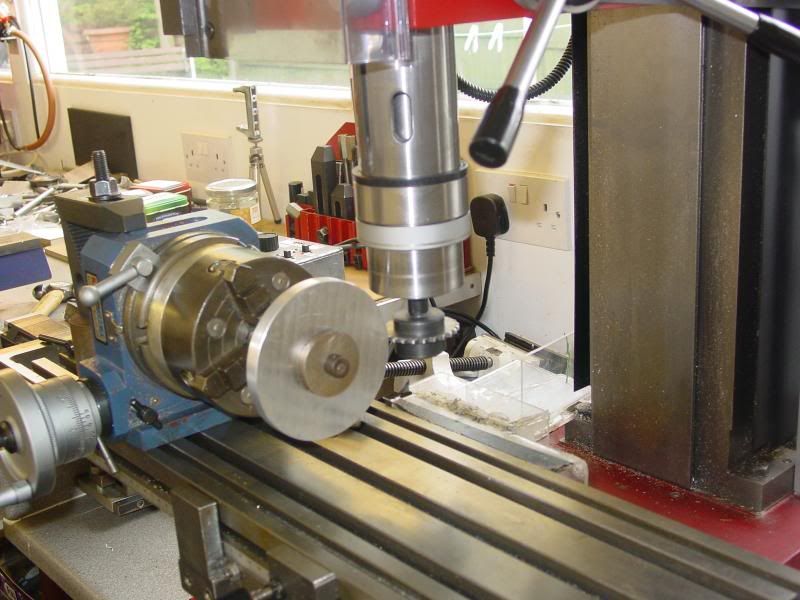

All the teeth cut

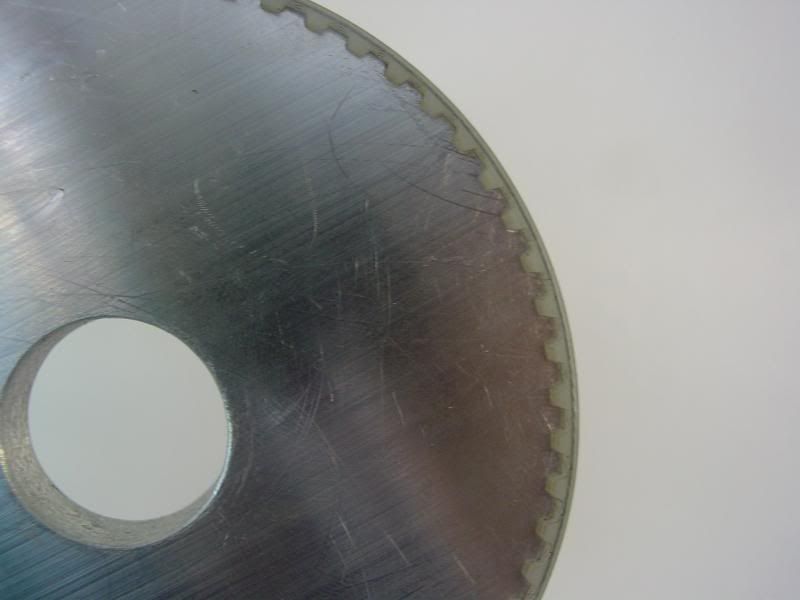

Atrial fit of a T5 belt.

It needs to be cleand up with a small file and have the sharp corners knocked off the teeth but its not bad.

Heres a bit of video to show the procedure.

Got to fit the new gear to motor next and refit to the mill. A job for another day. I'll post more when I get it done.

Cheers

Rich