Hi

For the sides and top I'm using 10mm oak faced mdf, another skip find.

Cut a strip off about 85mm wide.

Cut into slightly over size lengths

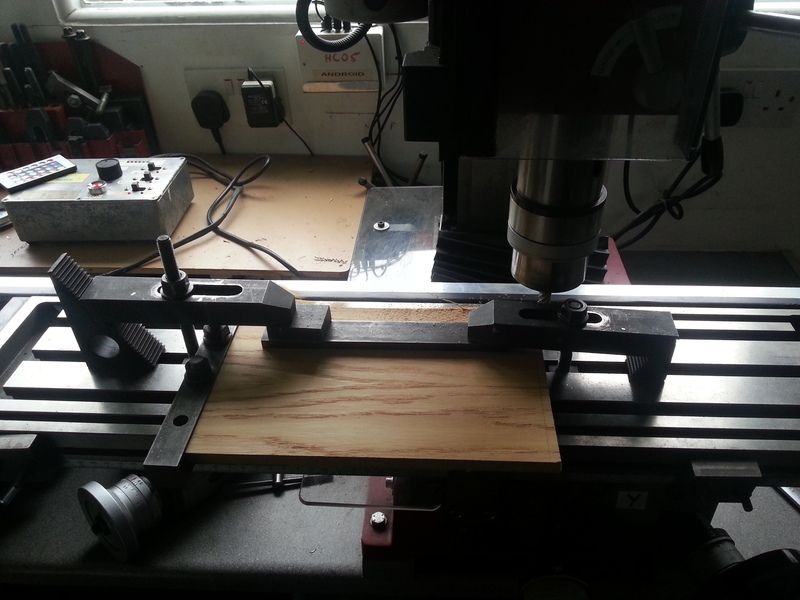

And machine to width in pairs

My mitre saw

Cut one end to 45°

Each side is numbered with a corresponding mark on the base. Holding the piece on the base mark the other end.

And cut, slightly on the waste side. A disc sander is a good way to bring it to size.

Now cut the other 3 sides until a good fit is achieved

Collect some of the saw dust

These cheap little corner mitre clamps are very handy and can be found in pound shops

Glue and assemble

A few extra clamps to hold things together

Leave for 24 hours and we have this

Mark out the size for the lid and cut out slightly over size

Machine to size

Cut a rebate 8mm deep 10.5mm wide

A test fit

Glue in place

This is a neat little trick an old woodworker taught me many years ago. A bit of wood glue and some of the saw dust collected earlier on a bit of scrap wood

Mix together and you have the perfect match filler

Ideal for the small gaps here and there

Clamp up with some scrap wood

Thats it for now

Cheers

Rich