Here you go Mike....something it does well!

Making bolt hexes!

In use, to make a hex on a bolt, it only takes 3 minutes to get a hex generated on a small bolt. It must be used with a spindle dividing device. There are many ways of doing that. Mine is mounted on the front of the headstock and picks up index holes I put in the backplate of the 5C collet chuck

In the first picture, the index pin is swung up and away and not in use. You will notice in my design, the end of the pin is spherical. This lets me adjust the position rotationally of the work piece while it's locked in the chuck. In the next photo, the pin is engaged with the index holes in the backplate of the chuck. To index, Only the cotter locking the pin is loosened and the pin raised and the chuck rotated. If I swung the block, I would loose my zero position...

If I inadvertantly turn the lathe on without backing the pin out, as us humans are prone to do.... the whole thing swings up and out of the way all by itself...so nothing gets damaged.

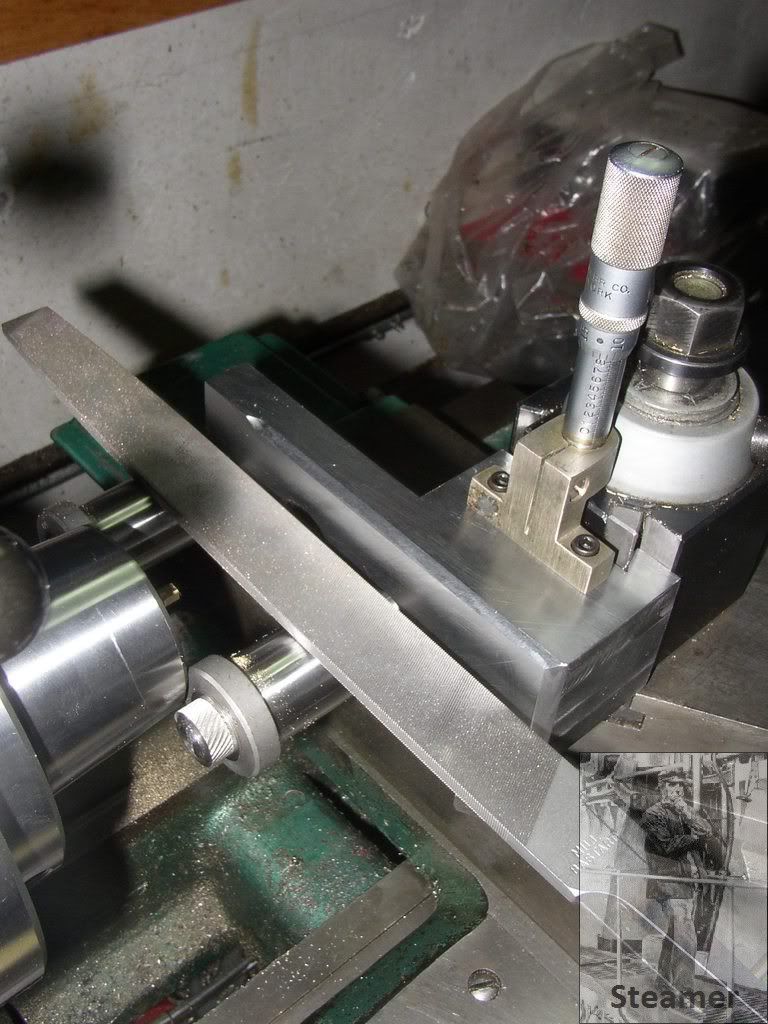

The file shown has a safe edge. A safe edge file has a side that has no teeth. That edge doesn't cut. In the photo above, the safe edge is the narrow edge in the foreground. In use, this safe edge is brought up against the shoulder of the rollers and the roller shoulder is used as a depth stop.

In use, the part is turned to the "across the corners" diameter and the lathe is stoped. The index pin is brought into engagement. the tool on the toolpost is removed and the filing rest is installed. The micrometer thimble is adjusted such that if the file is layed across the two rollers, the fill just touches. NOW turn the thimble down about .010" and lock the tool post. No need to reef the toolpost lever. Just snug

Take a cut on the first flat with the file. Continue filing until the file touches both rollers and ceases to cut. Make sure the safe edge of the file is up against the rollers also.

Now index the spindle around 180 degrees by, in my case, 12 holes. Lock the indexer and without changeing the position of the filing rest, cut the second hex flat. Once complete, roll the saddle out of the way and measure the dimension across the flats. Say you wanted .1875 for a final dimension and the dimension you measure is .200. The difference is .0125. To take this much off the across the flats dimension, we must lower the filing rest by .0125/2 or .00625.....OK call it .007"

Unlock the toolpost, and rotate the micrometer thimble by .007, lowering the filing rest and then relock the toolpost. Now take the remaining .007 worth of stock off the flat your on, and then index 1 flat, and cut to full depth. Repeat this until all 6 ( or 8 or 12 or whatever) flats are cut to full depth. You will be spot on the .1875 dimension and additionally, you will be DEAD concentric as the flats were cut while still mounted in the lathe that the diameter was cut on.

It sounds lengthy....but it takes about 3 minutes to do this whole procedure....and the finish is very good.

Quicker than setting up the indexing head on the mill....

Dave