Thank you all for the kind comments.

I have had a few moments of difficulty with the cams, I read through a lot of threads on this and other forums about how to make the cams.

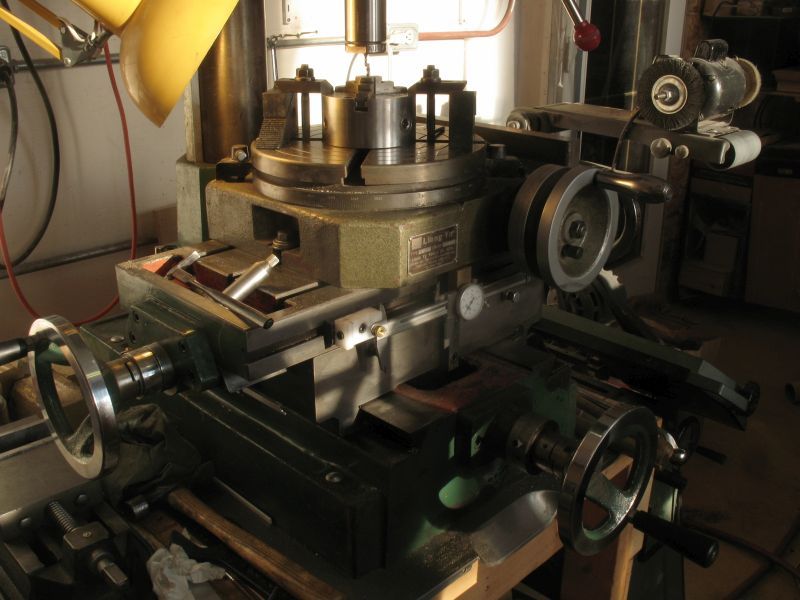

My first attempt was to make a pair for each cylinder, I turned up a blank on the lathe bored and pinned it to a 1/8th shaft of drill rod then transferred the chuck to the rotary table. I had drawn up a chart with the rotary table and marked off the degrees the first cam went well I flipped over the pair to cut the second cam and realized the old mirror problem and cut the second cam the same as the first.

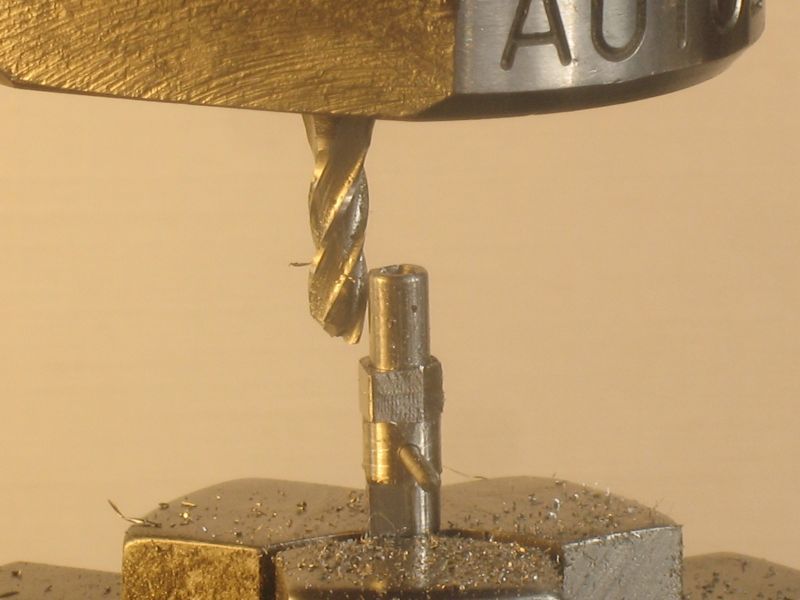

in order to confirm I went to rotate the cam and grabbed the wrong handle

and wound the work into the cutter chipping it and bending the shaft.

Costly mistake, I usually remove the mill table wheels when doing rotary work, for just this very reason.

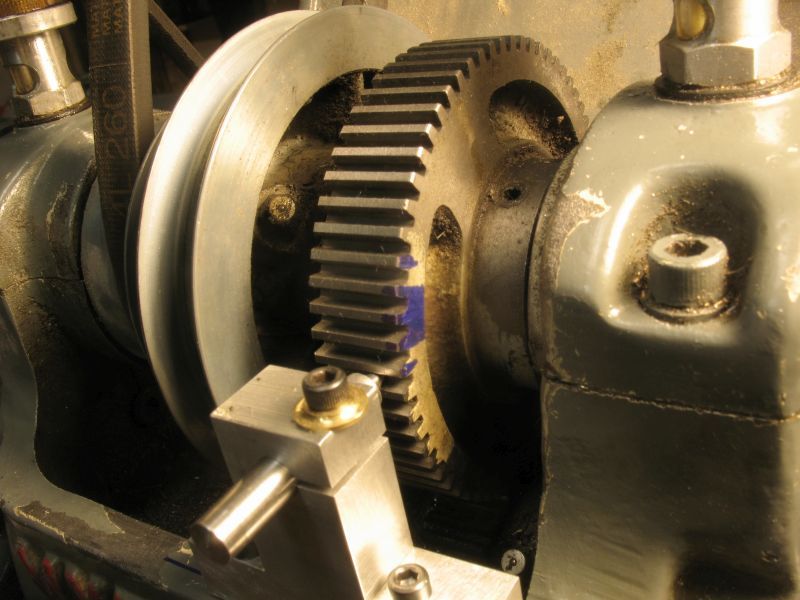

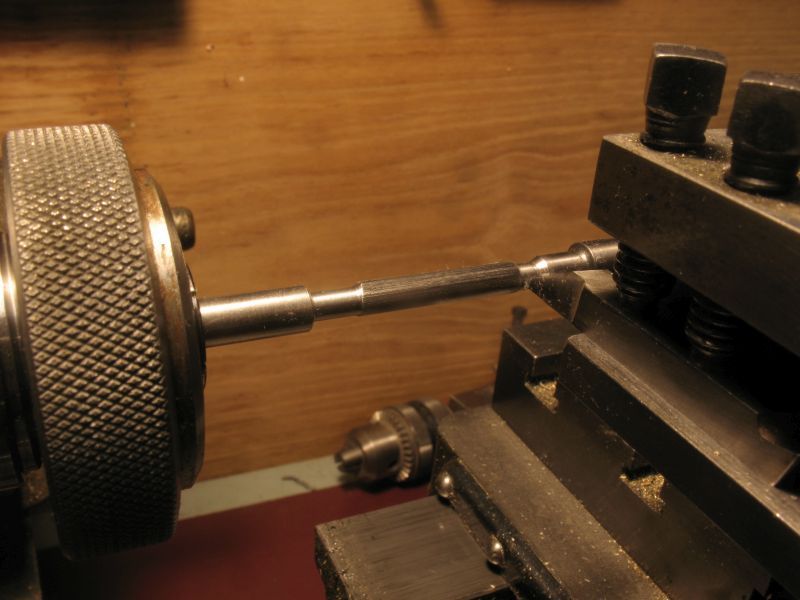

This episode caused me to reconsider the methods I was employing, I decided to make the cams using the lathe as a shaper. the first order was to add the indent device to lock the spindle using the 60 tooth main gear normally used for the back gearing on the Myford.

I did a drawing showing the progressive cuts of the shaping bit. and the tooth number to index to.

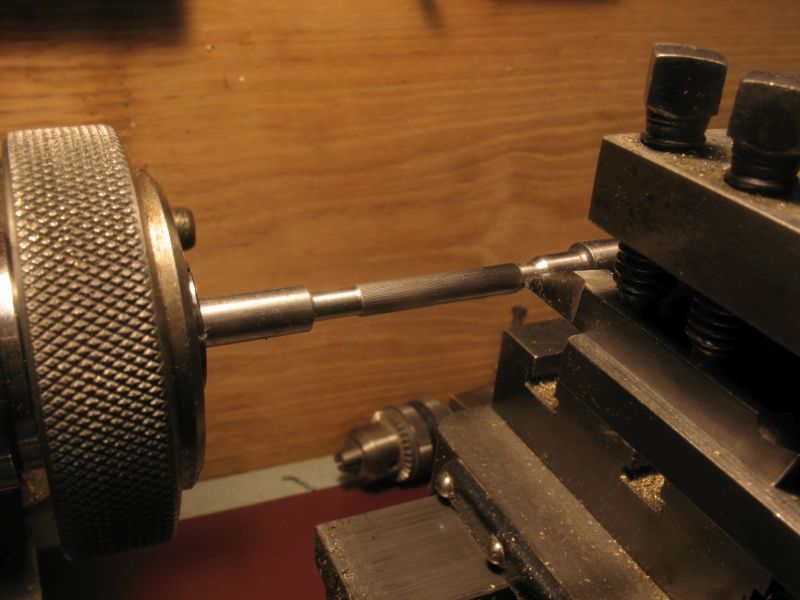

as I progressed with the ever deeper cuts a I also marked the gear with a blue marker progressing down to the half way round the diameter of the tooth to the 14th tooth either side of the lobe apex each cut was gust under .001" and cut very nicely.

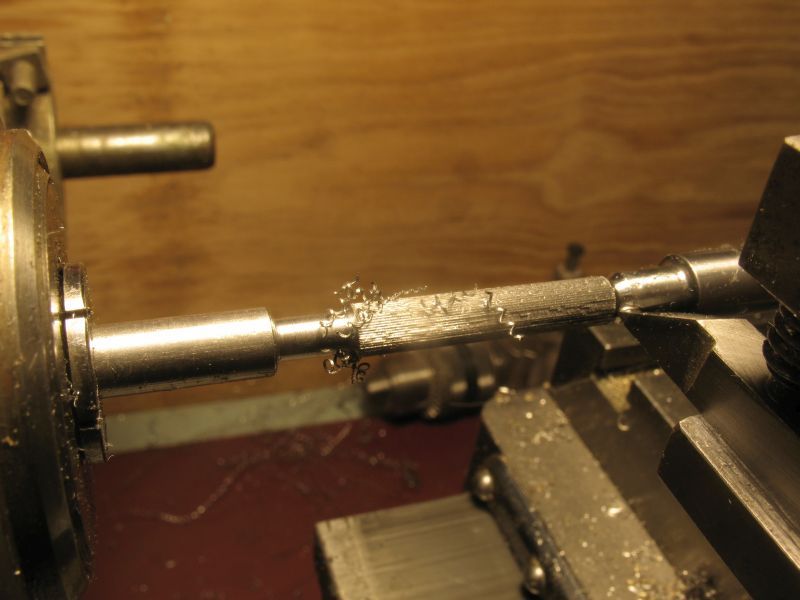

After this cut I rounded the tip a little more, to about a .01 radius

the results are encouraging I only have about .008" to go before the final clean up and polishing

The long cam form will get bored and reamed to 1/8th then drilled for taper pins and then parted off and hardened finally slid onto the shaft and pinned once the locations are set.

Mike