Hi

I'm sure we all try to squeeze that extra little bit out of our machines by making jigs and fixtures to increase their capability. You could argue that if your machine isn't big enough then you need to buy a bigger machine but when you are on a budget thats not always possible. I'm lucky enough to have an X3 mill as well but I do love my little X1 especially for smaller stuff, the finer feeds are more controllable. I have made some mods to the mill already. The first mod was to buy the longer table and leadscrew, that transforms the machine. I have also fitted DRO's to all 3 axis and a power drive to the Z axis. One area where these mills suffer is the lack of height on the Z axis. With a 4" rotary table and chuck fitted and a keyless chuck in the quill there isn't enough room for a drill let alone the work piece.

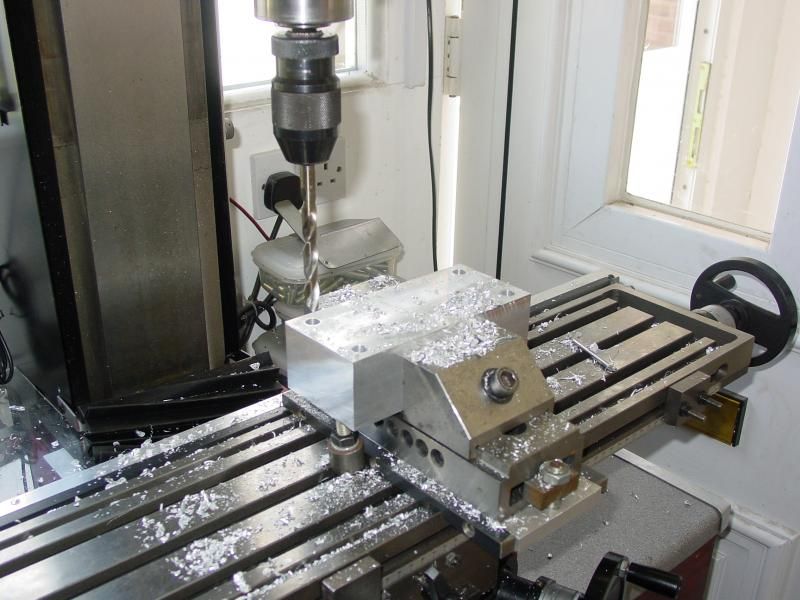

A quick and easy mod is to fit a spacer block under the column. I have used a piece of aluminium 170mm x 73mm x 50mm. It has been fly cut on all surfaces then drilled. The original fixing bolts are 8mm, I drilled the holes 10mm to give easy clearance. On my machine I spaced the holes 50mm centres and 135mm centres.

Of course longer socket head bolts will be needed.

It is possible to fit the raising block on your own, the weight being managable but its easier to have an extra pair of hands.

The result is a very useful 50mm increase in Z axis height.

No other mods to the machine are needed to fit the spacer and if needed it can be removed in less than 10 minutes.

Hope you find this useful

Cheers

Rich