As I mentioned on my 'micro-lathe maybe' thread...things were going to slow down.

Here's why...

I got involved with a couple of friends in a 3D printer project.

Except it's not just 3D printing.

I got a printer kit and instead of installing the extruder (print head), I installed a laser.

LASERS OF THIS POWER ARE DANGEROUS!!!

They can blind you in an instant. Precaution and proper safety procedures are required.

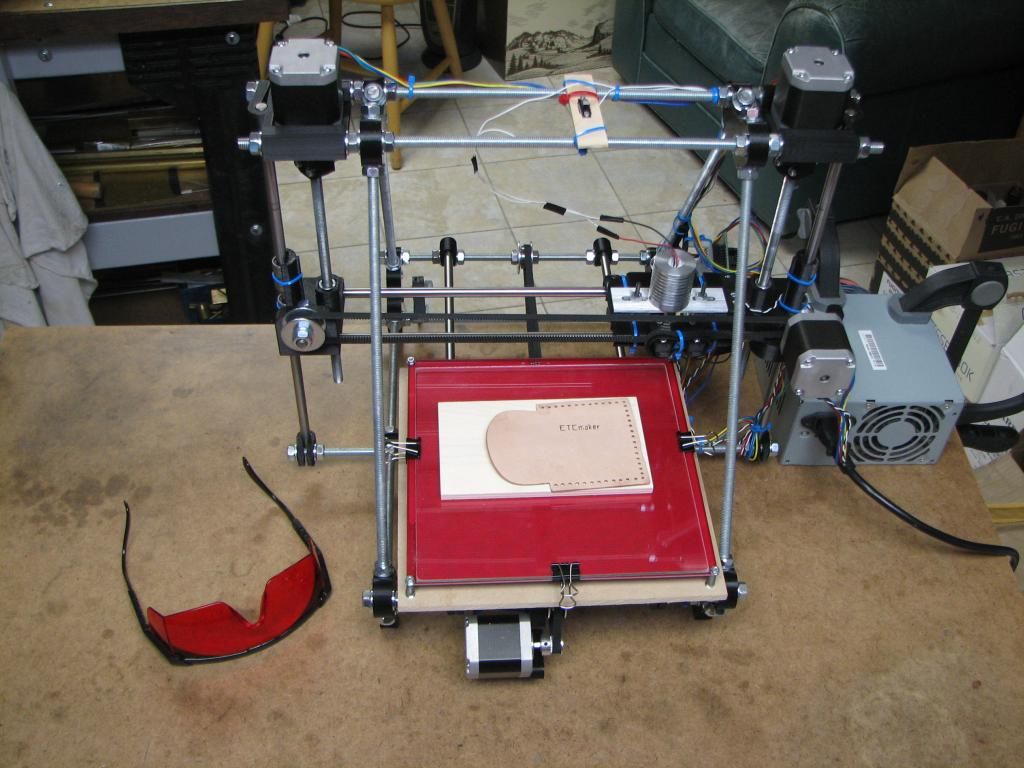

So here's a pic of the printer and the safety glasses.

NOTE: Safety glasses are not the same for machining and lasers. Nor are they the same for different wavelengths.

BE SURE TO USE THE APPROPRIATE GLASSES!!!

And keep everyone out. Standing across the room is not good enough. That beam can ricochet.

I machined the heatsink for the laser.

Here's a video doing some engraving on a piece of leather.

What a stink! Needs a fan to keep the smoke away otherwise it interferes with the beam.

NOTE: Depending on what you burn...be sure the fumes are non-toxic. Better yet...exhaust outside anyway.

This was just an initial run. Calibration is not complete.

As you can see...it uses a blue diode laser. It won't cut/burn/engrave certain materials depending on the materials' ability to absorb that wavelength.

Now you can see why I was talking about processors and software earlier.

This uses an Arduino Mega (Atmel 2560) processor board and stepper motor driver shield (daughter board) with Pololu drivers.

I use the Arduino IDE but SlickEdit as my editor.

I wrote my own PC program (Visual Studio using C++) to transmit g-code instructions to the printer.

The firmware in the Arduino board is Marlin which I had to modify in order to control the laser.

The project is fairly long term and given it's not really related to this fine forum I won't bore you (too much) with it.

Just wanted to let you all know what I was up to.

Not that I tell you everything.