Jim, Dean, and Chuck: Thanks for your comments. I'm glad you all looked.

A few posts back I showed how I intended to make a valve leakage fixture to

screw the head onto and apply pressure into the combustion chamber.

To further that idea, I made a plug to screw into the spark plug hole. I

have a spark plug I could have screwed in there, but I felt better about using

this plug. I threaded it on the lathe, which is still not something I'm very

good at, but practice, practice, practice. I cut flats on it for tightening.

I lapped the valves with toothpaste. As I had heard recommended by gbritnell,

I put the stems in a small drill chuck which gave me a good handle, and I could

use the weight of the chuck to provdide a steady pressure as I rotated back

and forth, sometimes lifting up off the seat a little to distribute the

compound. I have no meaningful pictures of that operation.

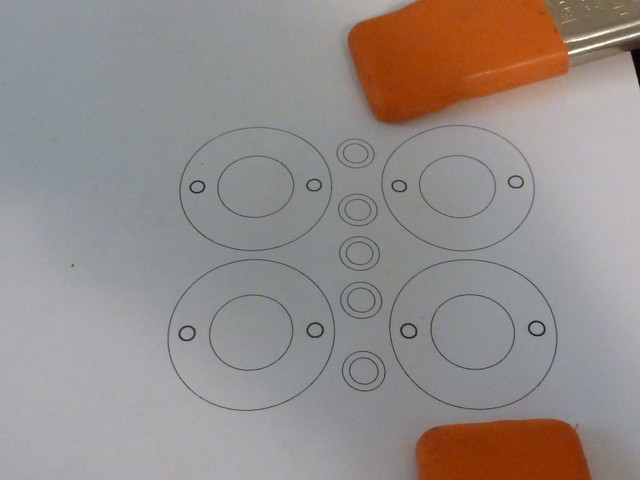

I printed out outlines for head gaskets and clamped the printout over a

piece of .010 teflon film (which you can't see here), and that over a cutting mat; then used an x-acto

knife to cut out a couple of gaskets. The small circles are gaskets for the

spark-plug hole plug shown above.

Here's the head on the leakage fixture with gaskets and plug in place. A

hole for the rocker arm post goes all the way through the head, but it's

plugged from the inside.

I submerged the fixture in water and blew on the hose as hard as I could.

Well, the fixture worked... I saw quite a few bubbles coming out of the

exhaust pipe hole. Heavy sigh. I lapped the exhaust valve some more, examining

the valve under magnification for a tell-tale dull gray band I had read about. I did see a band

on the intake valve that was not quite so pronounced or complete on the

exhaust valve. I lapped til the band looked similar on the two valves.

Back on the fixture and under water, and guess what? No matter how hard I blew

there were no bubbles.

I admit I don't know if breath pressure is enough to prove anything, but I'm

actually very hopeful. I'm kind of glad I got bubbles the first time so that I

had a point of comparison. I'm going to call the head done for now.

Thanks,

--Tim