I'm playing catch-up with the posting, so onto another part! The valve rods are the last part of the valve linkage that needs doing. I used 5/32" precision ground stainless, but the rods have a ring on the end that needs to be machined, so I had to silver-solder on some lumps of 1144SP.

A small step was turned on the ends of the rods to fit into a short 1/8" hole in the blocks, and they were fluxed and set up with a solder ring (56% silver) and a few small bits of solder at the bottom of the holes.

In hindsight, this wasn't the best setup; the boiling flux pushed the rods out of the holes, and they had to be pushed down. A small cross hole would have been a good idea (but would have required boring, rather than drilling the cross hole later).

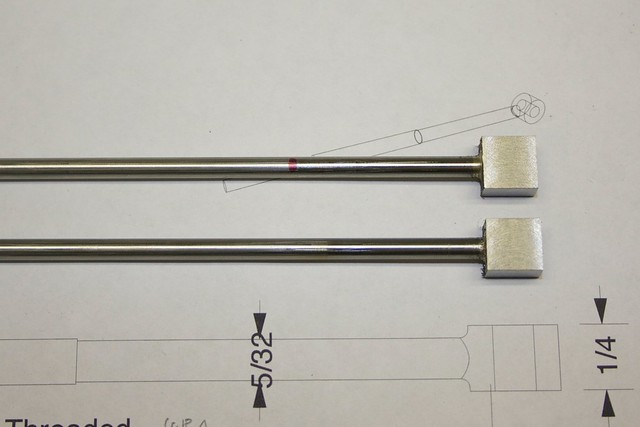

But with some twisting of the rods while the solder was liquid (which was necessary to wet the stainless) I got two mostly good joints:

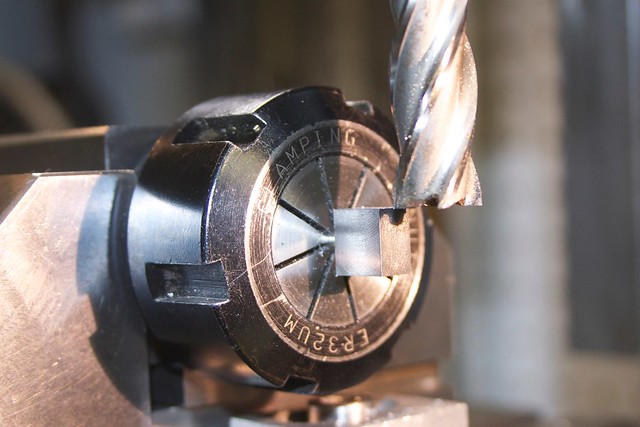

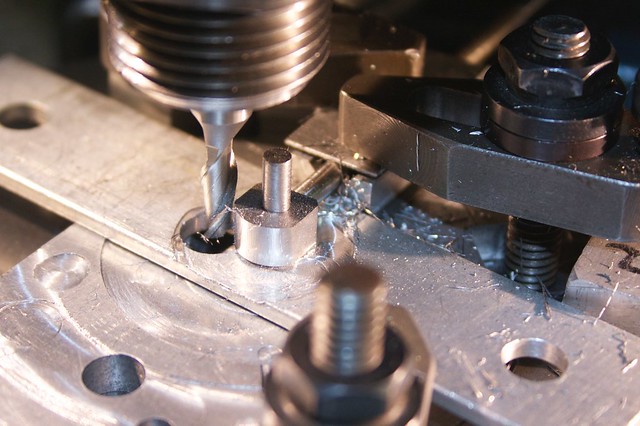

After cleaning off the flux, these went into a square collet block to square up the end lump relative to the rod with some gentle cuts:

leaving me with this:

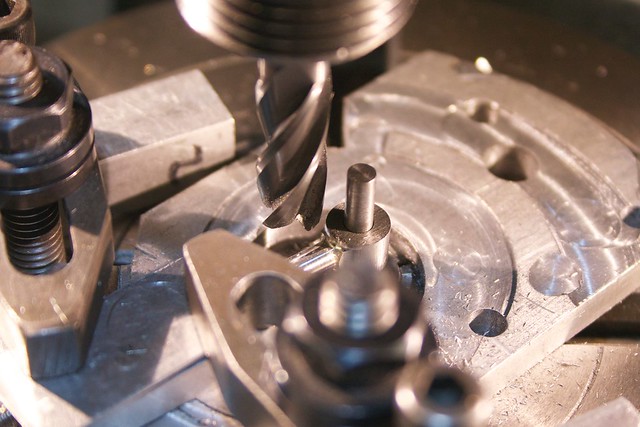

Now I could hold the blocks in the vise to drill the cross hole:

However, when drilling I could feel the drill wandering, because of the inside hole and the harder silver-solder, so the hole was opened out to reaming size with the tiny boring bar:

then reamed.

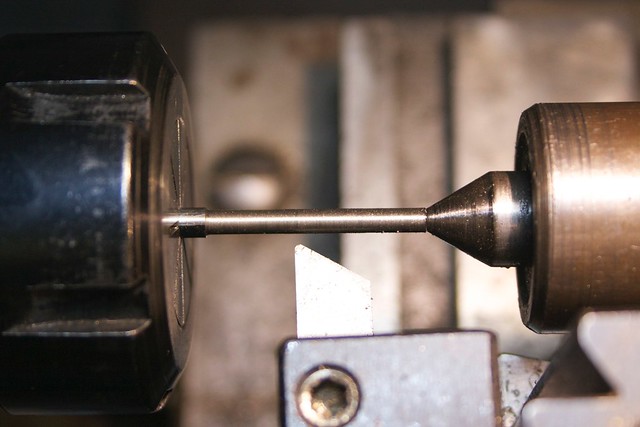

Now I can flip the part around to hold in a collet to turn the outer end down to 1/8" with a center:

before threading the central section 3BA:

Even though the core diameter of 3BA is a hair over 1/8", the die marked up the 1/8" section which was somewhat annoying, so that had to be smoothed out again. Yet another reason why I should learn to do single-point threading!

One thing I've found with this 5/32" SS rod is that, despite being "precision ground", it's actually about a thou oversize (I suspect so they can also sell it as 4mm) so I had to take it down with emery paper to fit the glands:

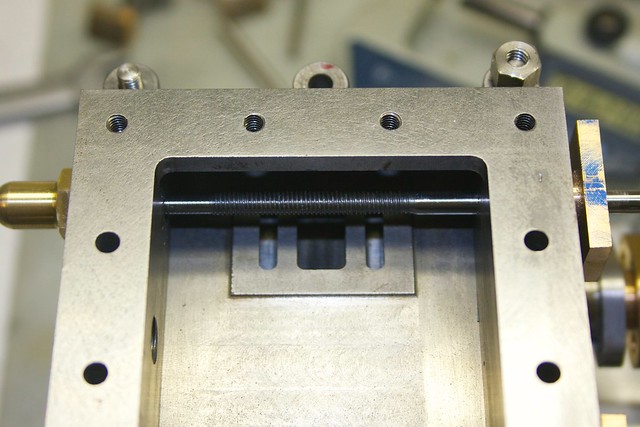

A fit in the steam chest shows that the threads overlap the valve locations correctly

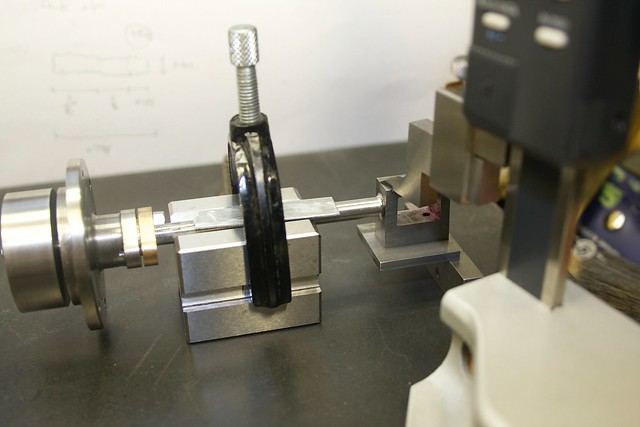

The final operations were rounding the ends on the rotary table:

with the radius end mill just skimming the rod for the join radius:

and a bit of filing blended the radii quite nicely:

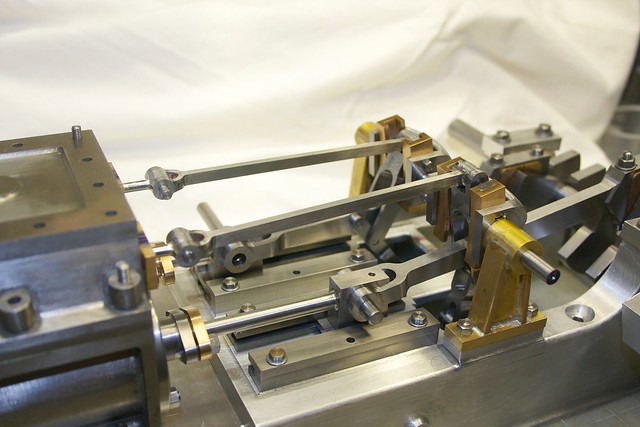

With both done, it's time for a trial assembly

I've amassed quite a collection of parts!

The crossheads needed a bit of a skim off the bottom to match the piston rod locations after bolting down the cylinder block, and to compute how much, I measure the distance between the top of the piston rod and the top of the crosshead when screwed in:

and the same distance after assembly (but not screwed together) with the crosshead in the crosshead slides. This told me I had to skim about 2 thou off one, and 8 thou of the other:

After a bit more fitting work everything goes together (with temporary pins!) and it's starting to look like Muncaster's Joy's Valve Gear Engine!

It's a little stiff at one point in the cycle, so I need to figure out where that's coming from. Next will be valves, and the final parts are the flywheel of course, and the handle that controls the valve timing.

Thanks again for following along on this adventure!

Simon