This morning it was time to get the crankshaft ship-shape! I carefully set up in the band saw, ordering the cuts so that the bit of rod being cut was the same bit clamped in the vise (thus avoiding undue forces on the glued and pinned joints):

That meant inside followed by outside cut on one side, flip the part around and repeat. There's a parallel to prevent the part from rotating under the force of cut, and some shims under the ends of the webs for support. Of course I was very careful to prevent the saw from dropping down and cutting the journals.

The saw cuts could then be cleaned up by milling, again following the "clamp the part you're cutting" rule:

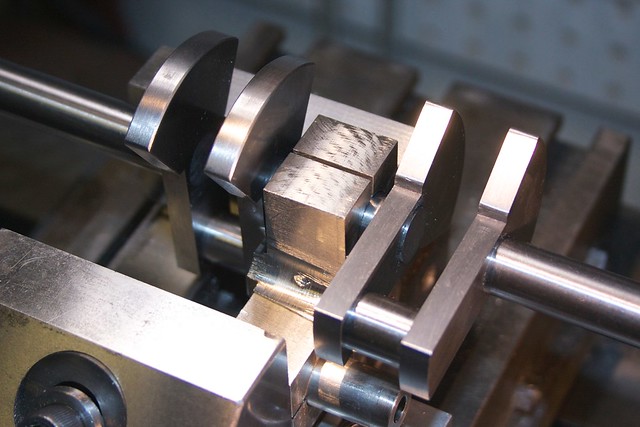

The inner webs require something a bit more fiddly to hold them. As part of the great silver-soldering fiasco, I had made the fixture you see here to hold the parts for soldering (but never used it):

but I finally found a use for it to hold the inner bit of the main shaft for cleaning up these ends:

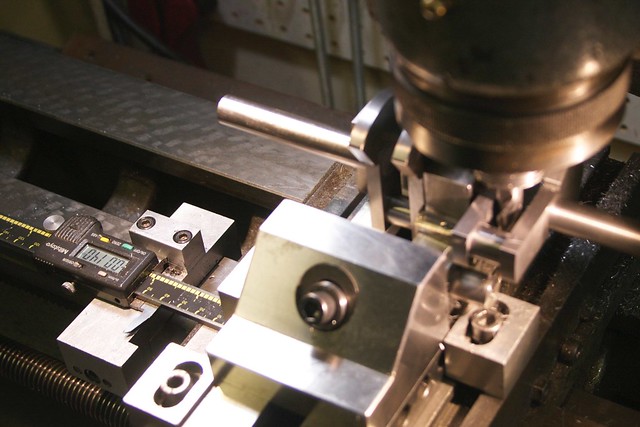

A quick note on how I mill up to a flat surface like this. I have a poor man's DRO (an old indicator clamped between the carriange and a carriage-stop):

I'll position the tool for the cut, and then crank the dials until the tool just touches part of the finished surface, then zero the indicator. With an end mill, it's good to rotate the spindle a partial turn and do this a few times, since different parts of the tool will touch. If you suspect the part isn't perfectly lined up, do this on both sides of the cut and take the one with least depth of cut.

Now touch the tool on the bit to be milled away, and note the indicator reading; this is of course how much to remove. Now you can start making cutting passes, being pretty confident that as you get close to zero, you're approaching the finished surface. For these cuts I had about 0.025" to remove and did passes of about 0.004".

With this technique you should be able to get within 0.0005", with the remainder easy to clean up with a file. Here's a cut up to the finished surface, and it shows that either my vise is out of tram, or (more likely) the web isn't quite square:

The four milled surfaces were then cleaned up by draw filing, and given a bit of emery-on-a-stick.

Now we're at an exciting point of first assembly

I washed some parts, found a couple of bits of 1/4" rod to put in the crossheads, and put everything together. One of the bearings needed a bit of fitting to go between the webs on one side, but apart from that everything fit and turns over fairly smoothly

Turning it over found a bit of interference between the conrods and the base, which was quickly relieved with a bit of filing (will be nicely profiled later):

and the slides will need a bit more fitting before I can tighten them down. But, hey, this is finally starting to look like something:

I think I'll do the cylinder covers next, and then I'll be building up the valve linkage parts from the bottom up. That should be fun!

Simon