Hi

Thanks Jim.

Funny how you think you are getting on well only to find you have made a ^&**%$ up of things.

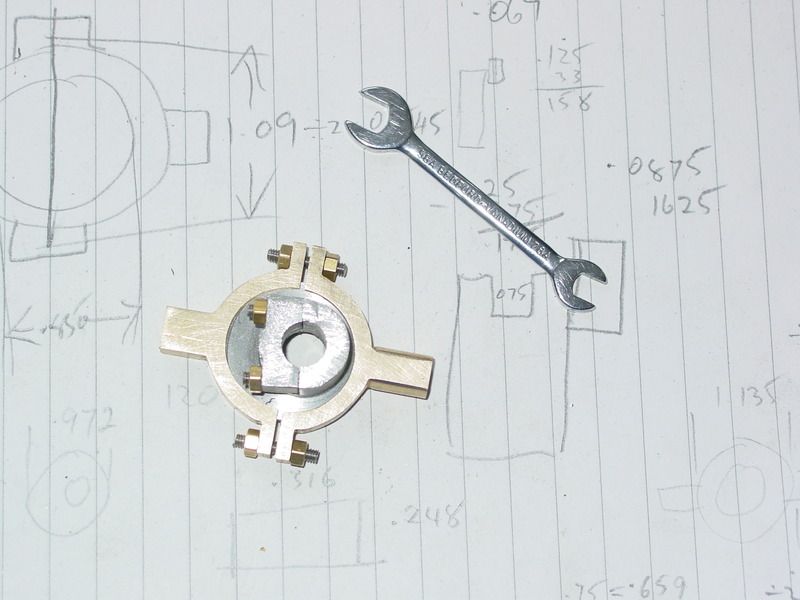

The sheave is drilled then tapped for the link rod.

Then drilled through at where the joint will be

Cut in half with a slitting saw. This one is only .015 thick.

Its at this point that I found out I had made a mistake.

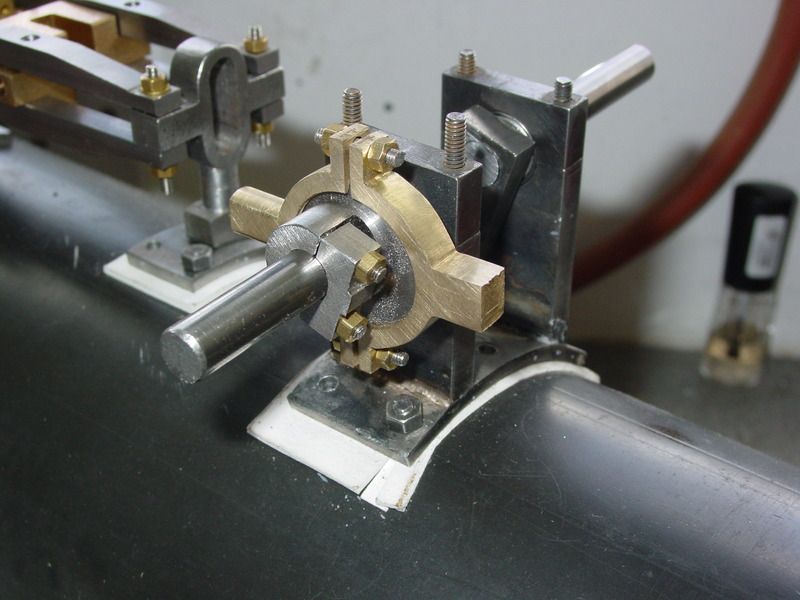

The sheave didn't fit the eccentric

I had cut the groove .040 undersize.

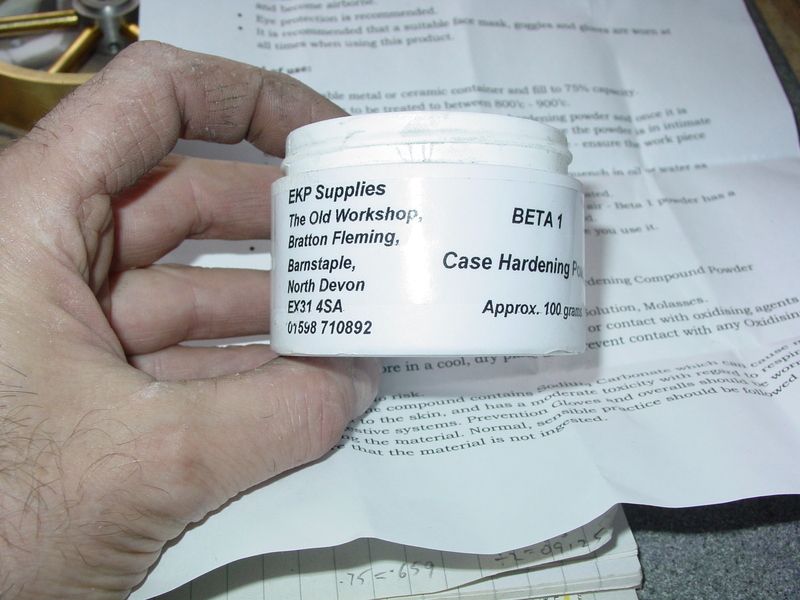

Unfortunately there was not enough materilal on the eccentric to turn that down a bit. I was almost resigned to scrapping it and starting again when I had an idea. On another project I have been wondering whether or not cutters can be made from mild steel then case hardened. No time like the present to find out.

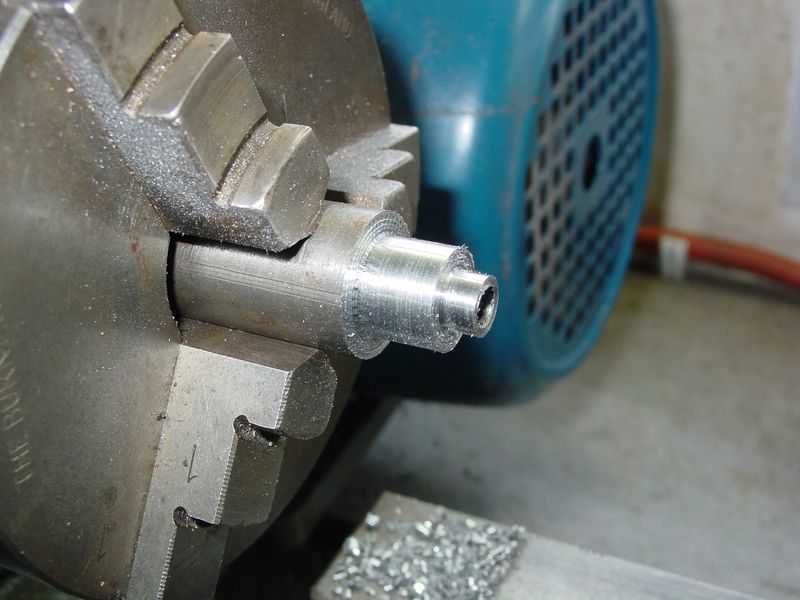

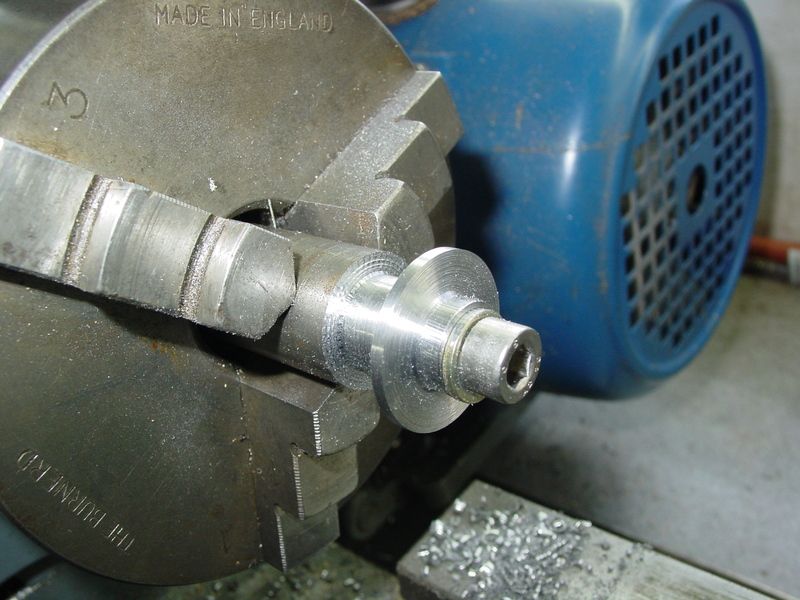

I made up a mandrel, the boss is 8mm then drilled and tapped 6mm

A piec of steel drilled 8mm fitted to the mandrel and turned to the exact size of the eccentric, .972

Over to the mill and rotary table to have the teeth cut

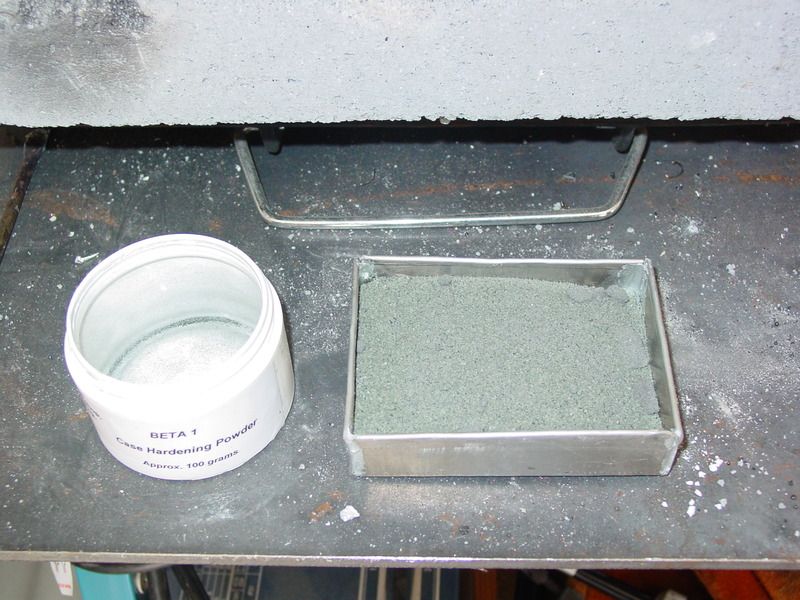

Heat to cherry red

And drop into the case hardening powder

Leave it for 30 minutes

After a clean up mount it on the mandrel and re machine the two halves of the sheave

It worked. Well enough to get the correct size. The teeth could do with backing off to give a bit more clearance but it cut the brass ok.

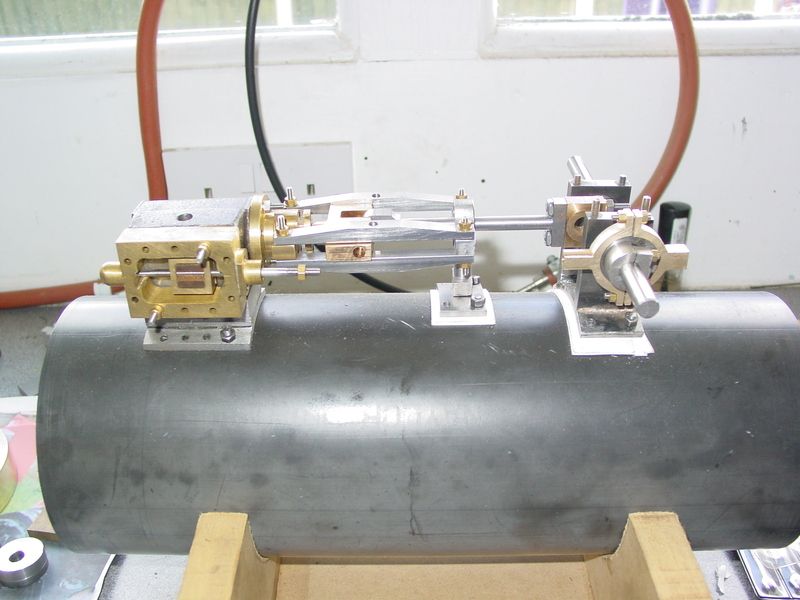

I have fitted the slide valve and housing to measure for the link rod.

Thats it for now. There is a little when I get the photos uploaded.

Cheers

Rich