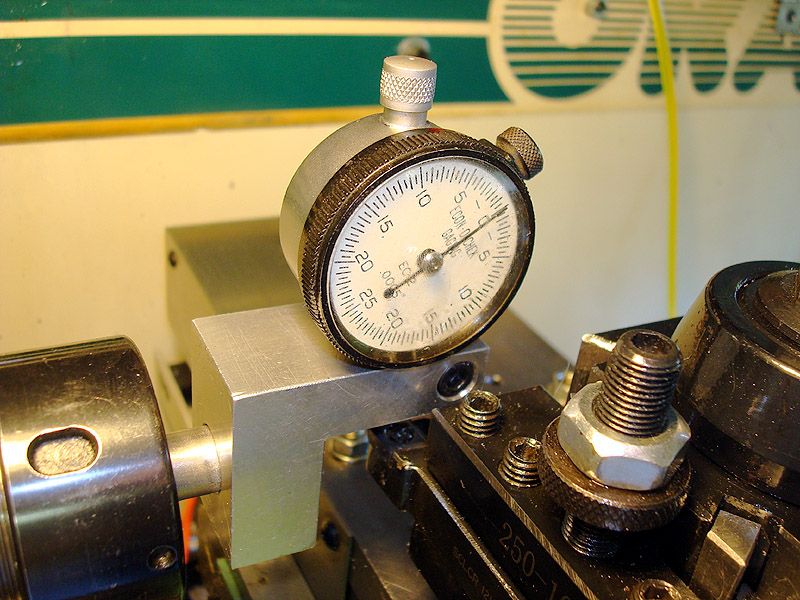

Iím most likely not the 1st guy to make one of these but I havenít seen another one like it yet. I found a small .150Ē travel D.I. dirt cheap on ebay. Itís small enough that it wonít hit the ways and explode if the spindle is accidentally turned on with it still in the chuck.

Itís calibrated with a .250Ē dowel pin that slides in & out of a close fitting reamed hole in the center of the shaft. The indicator dial is adjusted & locked so that the needle sits on zero with the dial tip extended exactly .125Ē when the dowel is removed. It works great and is very consistent. The only variable is making sure itís set at 90 degrees to the carriage but thatís pretty easy using a 6Ē square.

I use it on both my lathes but it really shines on the CNC lathe. Once the tip of the tool is adjusted on center and the QC adjuster is locked, I jog the tool back away from zero a bit, rotate the gauge 90 degrees away from the tool, re-square it then jog the tool back until the tip is spot on zero again & voilŠ! Instant DRO measurement for Machís tool offset table. I set up all 7 tool-holders in less than 20 minutes and that includes my multiple juggling/tightening/locking iterations to get them adjusted spot on zero in both directions.