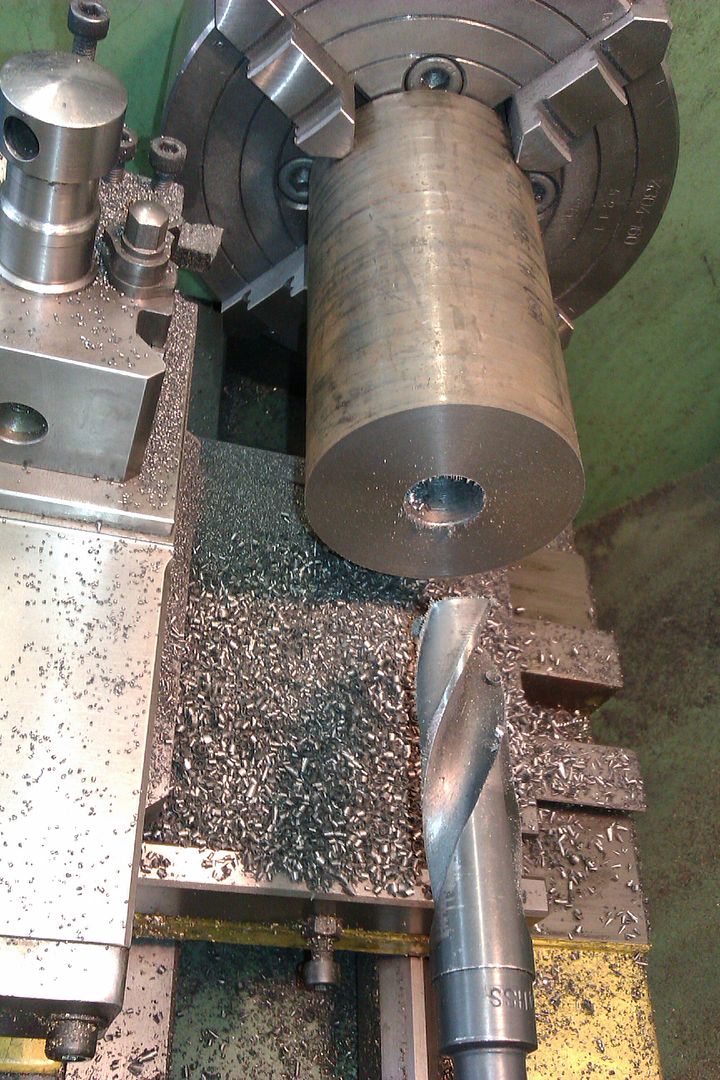

The liner is supplied as a large lump of cast bar about 70mm dia. This was held in the 4-jaw, faced and then opened up first by drilling in stages upto 3/4" and then boring to 0.0100" below finished size.

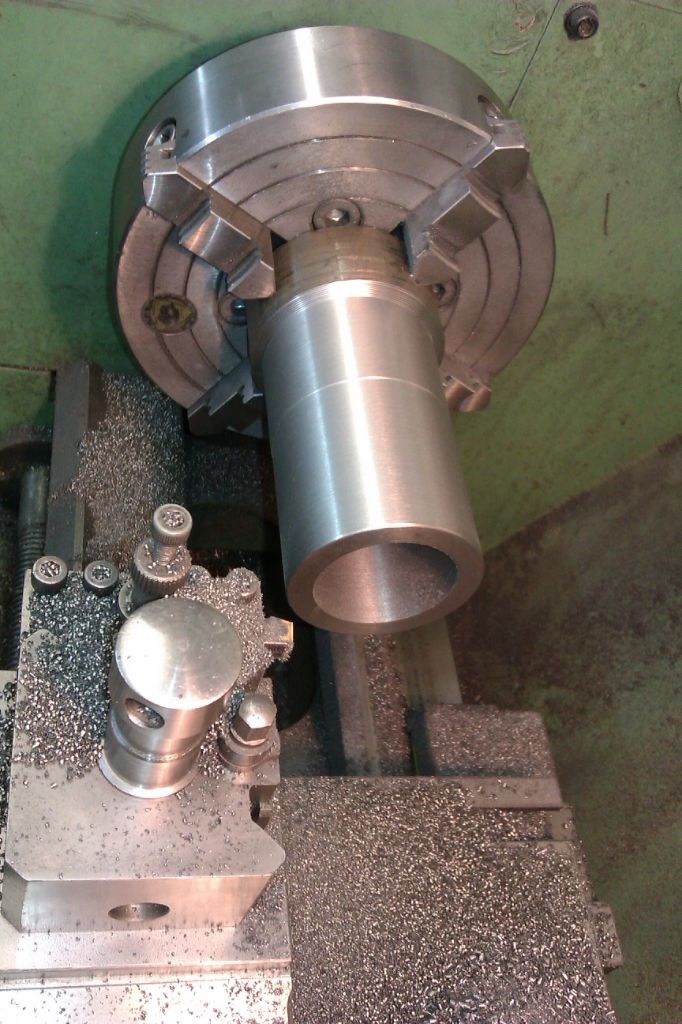

Approx half the length was then turned down so it was a nice firm fit into the base casting.

Here it is slipped into place, you can also see that I added a taper to help fitting the piston rings before I removed it from the lathe.

Before I forgot to drill it the coolant drain hole was added to the cylinder with an extended drill, this needed to be drilled before the liner is pressed into place.

The liner was then held by the machined end and clocked true before boring the waste out of that end and finally turning the different diameters to press into the cylinder. Not easy to see but there are 3 different dia all only a few thou different from the next.

The cylinder was then pressed onto the liner while still in the chuck using the tailstock to apply pressure and some Loctite for good measure.

After allowing things to dry over night I inserted packing and shims so the assembly could be bolted down to the cross slide. By doing this with things still in the chuck it kept all the bores true.

I then used a 35mm bar between ctrs to bore out the assemble to the required 1.750"

And without disturbing anything ran the sprung hone up and down the bore a few times.

And a quick look down the bore. I was pleased that the butt joint between liner and cylinder did not show so things must have pressed into place as planned.

J