Hi Guys, it's been a productive if somewhat interuptive couple of days. I finally bit the bullet and bought a shot blasting cabinet which arrived yesterday - the day after ordering it which is pretty good for 'free delivery'

and, talking of which, I had ordered some 6082 ali for the prop drivers and prop nuts late on Friday off Ebay and much to my surprise it arrived, post free as well, on Monday morning just as I started the con rods

Good service all round eh?.

The conrods are made from a tough aluminium called Alumec 89. It machines beautifully with an almost chromium like sheen and whilst it's easy enough to bandsaw it it's a real devil to hacksaw as it soon work hardens to that process. I first used it many years ago when working for a small jobbing workshop where we used to make moulds for a local blow moulding company and have had some scraps squirreled away for years

Prior to the first Etas made, all con-rods had been milled. Turning them had previously been fought shy of because of holding them to form the second ball end. The drawings were laid out with milled rods but the fact that this was not correct to prototype began to bug and the idea of turning a tapered split bush to fit inside a collet was conceived. Much to my surprise that proved to be an efficient manner of holding them and the rods for the Super Tigres and this latest batch were made with relative ease. The making of these were covered on the Tigre build but I'll run through it again as it may be of use. Apologies in advance if considered repeating myself

First off was to cut a slice of a small block then cut that into strips about 50mm long. These were quickly milled to square section .5mm over finished size then held in the SC4jaw turned to 11.1 diameter for about 30mm then reversed in a collet to give five round blanks

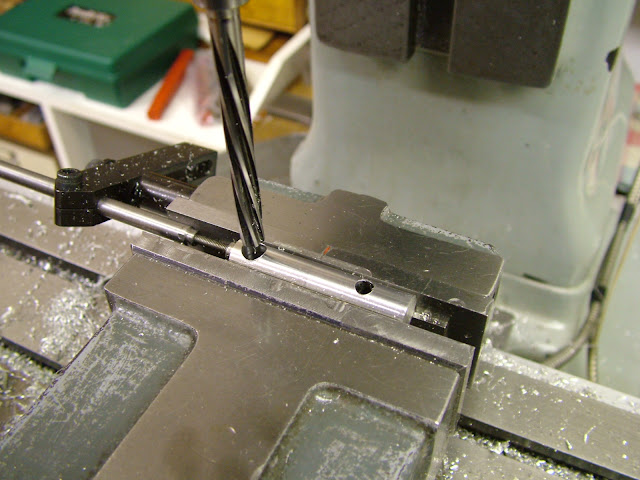

These blanks were then drilled and reamed on the mill, stops being set to maintain consistency

Held in a 7/16" collet the first (bottom) end was formed using the original tooling made from a small piece of GFS

Then it was extended out of the collet to turn the shank, supporting it with the brass bush which has a 30 degree taper for the centre to impinge upon and a 45degree taper to support the rod. The shank is turned parallel to it's major diameter first, then taper turned using the topslide to flair into the big end. The excessive overhang of the tool is to allow clearance of the topslide against the tailstock - one of the very few annoying limitations I feel about the Myford.

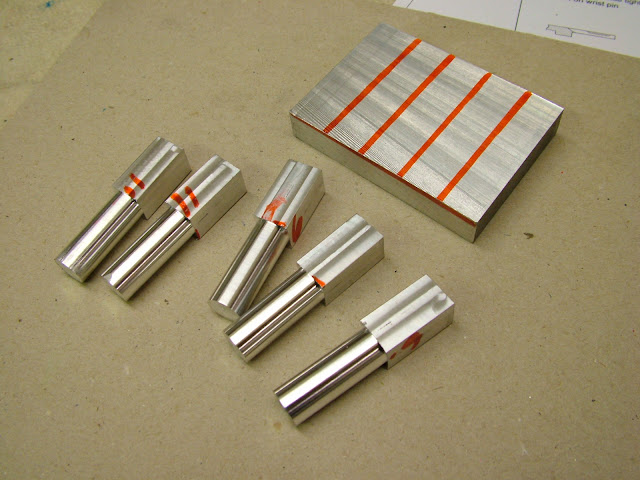

First stage looked like this along with the split bush turned at the same setting as the rods. The small end diameter is worked out

according to the length of the busht, drilled thru at that size then carefully bored until the taper cut finishes as it breaks the small end.

Holding this in a collet provides more than adequate gripping power to form the second ball end. Incidentally the tool is set symmetrical about the hole by eye, inking up and moving the topslide until both sides of the hole appear even

The finished little end....

... and the finished rods

Well there you are - a few more pics which I trust might prove useful to someone - there appears to be a lack of small engines such as these being mentioned on here - is anyone else making anything similar ?

I was hoping to have the prop drivers finished today too which would bring the ali parts to and end but time was not on side today so that will have to wait until tomorrow.

Regards for now Ramon