Liney RV-1 - A New Double Wide

Part 8

Grand FinaleThe speed build is done. Now to finishing and final assembly.

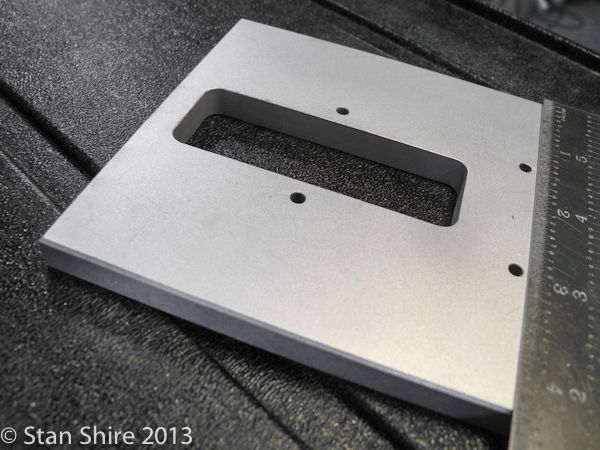

The base and flywheel will be painted. I cleaned them both with lacquer thinner. The base plate was bead blasted to give the primer something to grab.

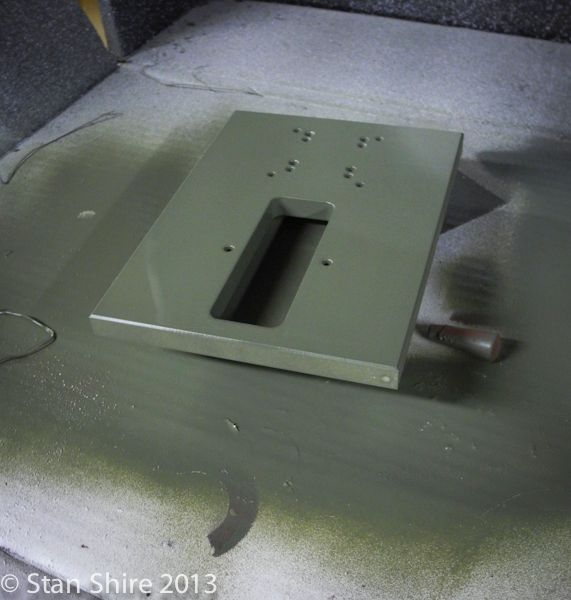

Iíve had good luck with this self-etching primer. A few light coats and itís ready for paint.

Also been happy with this masking tape. The paint does not creep under the edge. Since I had already polished the flywheel rim, I masked that.

While the paint was drying, I sanded and polished the valve block.

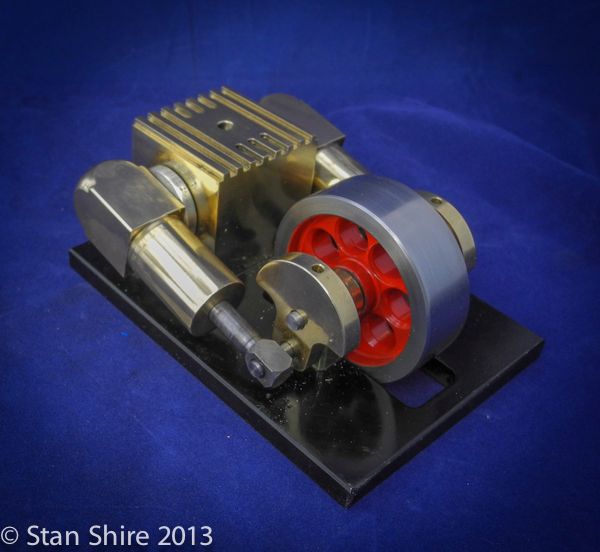

The baseplate and flywheel have three coats of paint and one coat of clear lacquer.

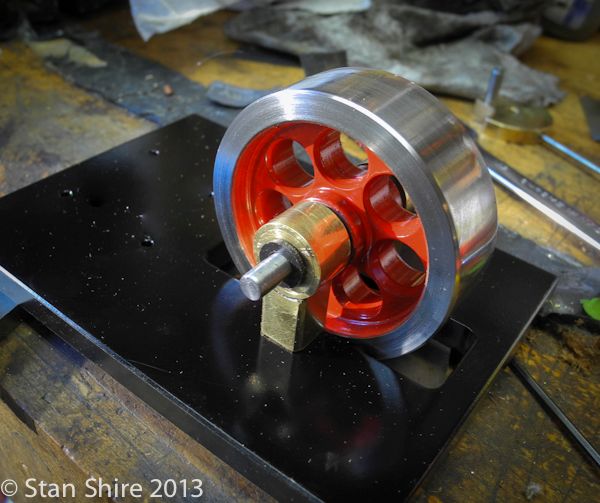

Assembly is begun with the flywheel and bearing towers.

Heading Billís advice about crank mis-alignment from his build, I rested both crank pins on a pair of

parallels and tightened the set screws.

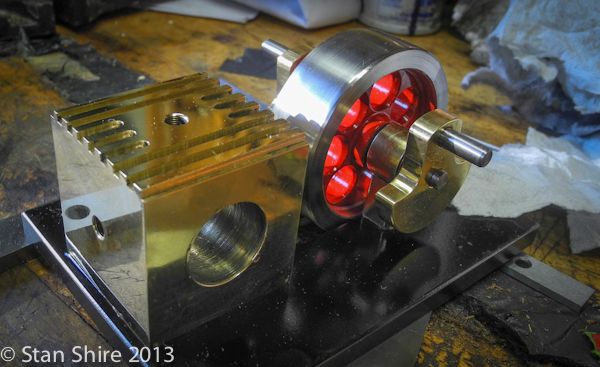

The valve block was next in line.

The rotary valve was slipped through the valve block, then one piston and cylinder was attached with a set screw. The other cylinder/piston pair was slipped on.

Thatís it. Iíve run it for about an hour and itís down to around 10 pounds although the compressor gauge isnít that accurate at low pressure so it could be less or more than 10 psi.

Thanks for watching.

Video will be posted in the Finished Projects section.