I picked up a bargain last night a Unimat Sl1000 three jaw chuck for ?11. No one wanted it because of the 12mm * 1mm thread. I can never understand these people chucks have back plates, you just remove the old plate make up a new one to fit your lathe and fit it.

For this chuck I took a 40mm noggin cleaned it up:

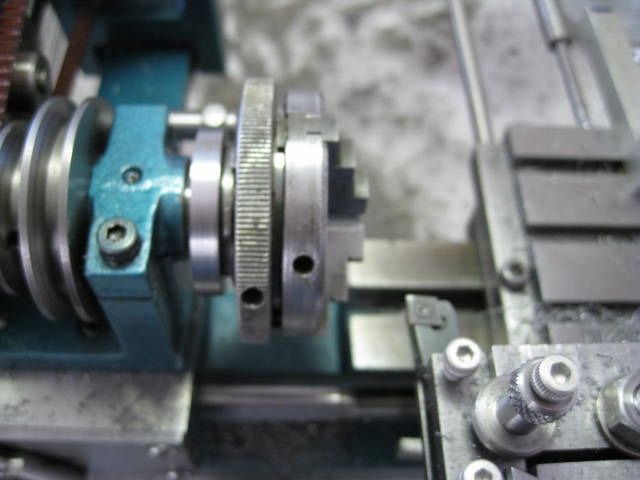

As you can see I actually made two backplates rather than one, it just meant that I had an opportunity for some character building to hand hacksaw the two plates apart. Back to the lathe and then used a 14mm * 1.5mm tap to tap the thread for the nose:

People have told me that using a tap to cut the thread for a backplate is bad practice but they seem to forget that the nose on the lathe has a register as well so the chuck is centered on the register not the thread. So using a boring bar the register was cut in the back of the plate and checked using the nose on my dividing head (sorry forgot the photo

) and the surface skimmed to chick it was square with the register.

The the new backplate was then put on the Cowells and the register for the back of the chuck cut on the new backplate before drilling and cutting the three 4mm screw holes. So a new chuck for my Cowells:

My plan is to use this new chuck on either my indexing head or the dividing head.

Jo